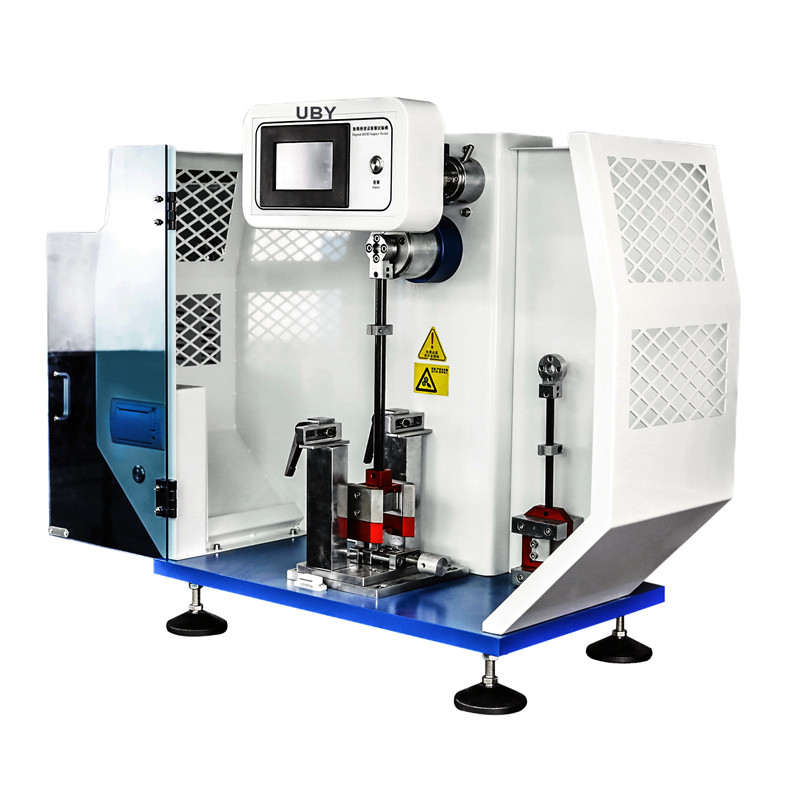

Gwajin tasiri hanya ce mai mahimmanci don kimanta kayan, musamman kayan da ba na ƙarfe ba, don tantance ƙarfinsu na jure wa ƙarfi ko tasiri kwatsam. Don aiwatar da wannan muhimmin gwajin, ana amfani da na'urar gwajin tasirin faɗuwa, wanda kuma aka sani da na'urar gwada nauyin digo, sau da yawa. Wannan nau'in nunin dijital kawai yana goyan bayan injin gwajin tasirin katako ana amfani dashi musamman don auna tasirin taurin kayan daban-daban waɗanda ba ƙarfe ba, gami da robobi masu ƙarfi, ƙarfafa nailan, fiber gilashi, yumbu, dutsen simintin, kayan rufewa, da sauransu.

Ka'idar aiki nadrop tasiri gwajin injishine sauke abu mai nauyi daga ƙayyadadden tsayi akan samfurin gwaji, yana daidaita tasirin da kayan zai iya sha a rayuwa ta ainihi. Wannan yana ba da damar kimanta ikon kayan don ɗaukar makamashi da tsayayya da karaya a ƙarƙashin yanayin lodawa kwatsam. Na'urar tana auna daidai ƙarfin kuzarin da samfurin ke ɗauka yayin tasiri, yana ba da bayanai masu mahimmanci don ƙirar kayan abu da sarrafa inganci.

A cikin masana'antar sinadarai, cibiyoyin bincike na kimiyya, kwalejoji da jami'o'i, da sassan dubawa masu inganci, jujjuyawar injunan gwajin tasirin kayan aikin gwaji ne. Yana ba masu bincike, injiniyoyi da ƙwararrun masu kula da inganci damar kimanta tasirin juriya na kayan da ba na ƙarfe ba, tabbatar da sun cika ka'idoji da ƙayyadaddun ƙayyadaddun da ake buƙata don aikace-aikacen da aka yi niyya.

A versatility nadrop tasiri gwajin injiya dace da kayan aiki masu yawa, yana sa ya dace da masana'antu iri-iri. Ko ana kimanta tasirin taurin robobin da aka yi amfani da su a cikin samfuran mabukaci, kimanta dacewar abubuwan fiberglass a cikin gini, ko gwada juriyar abubuwan da ke rufewa a cikin aikace-aikacen lantarki, faɗuwar injunan gwajin tasirin na iya ba da haske mai mahimmanci game da aikin kayan da ba ƙarfe ba. ƙarƙashin tasirin tasiri.

Madaidaicin yanayin ingantattun injunan gwajin tasirin juzu'i ya sa su zama kayan aiki mai mahimmanci don ayyukan R&D. Ta hanyar fahimtar yadda kayan ke amsa tasirin kwatsam, injiniyoyi da masana kimiyya za su iya yanke shawara game da zaɓin abu, haɓaka ƙira, da haɓaka samfura. Wannan yana taimakawa haɓaka mafi aminci kuma mafi ɗorewa kayan da ba ƙarfe ba don aikace-aikace da yawa.

Lokacin yin la'akari da gwajin tasiri, yana da mahimmanci don zaɓar adrop tasiri gwajin injiwanda ya dace da ka'idodin masana'antu da ƙayyadaddun bayanai. An ƙirƙira majinjin tasirin tasirin dijital na Charpy da aka ambata a baya don saduwa da waɗannan ƙa'idodi, tabbatar da sakamakon gwajin daidai ne kuma ana iya maimaitawa. Bugu da kari, injinan gwajin tasirin faduwa na zamani galibi ana sanye su da ingantaccen sarrafa dijital da tsarin sayan bayanai don kara inganta daidaito da ingancin aikin gwaji.

Lokacin aikawa: Juni-27-2024