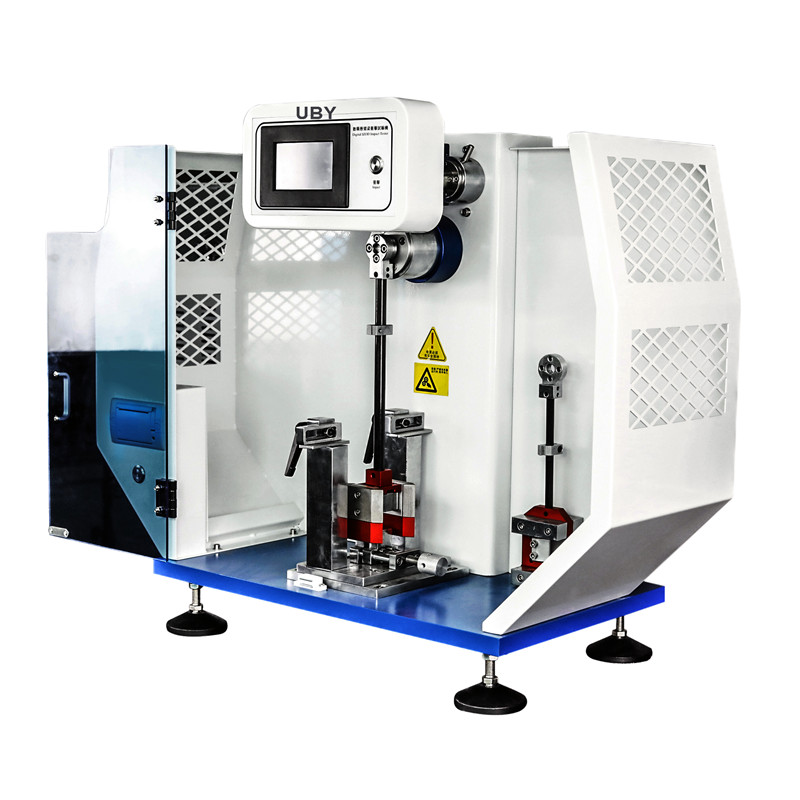

Kayayyaki

UP-3014 Cantilever Beam(IZOD) Gwajin Tasiri

Matsayin aiki

TS EN ISO 179-2000 Ƙaddamar da Filastik - Ƙarfin Tasirin Kayan Wuta

GB/T1043—2008 Hanyar Gwajin Tasirin Tasirin Filastik

JB/T8762-1998 Na'urar Gwajin Tasirin Filastik

GB/T 18743-2002 Hanyar Gwajin Tasirin Charpy don Sufurin Ruwa ta Bututun Thermoplastic (Ya dace da guntun bututu)

Halayen Samfur

A. Babban madaidaicin mai kula da hankali sanye take da nunin LCD wanda zaku iya karanta bayanan cikin fahimta da kuma daidai;

B. Lever carbon fiber na farko na kasar Sin (An ba da izini); yana yin nasara wajen yin gwaje-gwaje ba tare da girgizawa wanda ya haɗa da jagorancin tasiri ba, inganta ƙaƙƙarfan kayan aiki, da mayar da hankali ga ƙarfin tasiri akan centroid na pendulum, da amfani da rayuwa yana ƙaruwa.

C. Ƙididdiga masu ƙima na dijital da aka shigo da su, mafi girma kuma mafi tsayin daidaiton ma'aunin kusurwa;

D. Aerodynamic tasiri guduma da shigo da ball bearings ƙwarai rage inji gogayya asara

E.Lissafi ta atomatik na sakamakon ƙarshe, ana iya adana saiti 12 na bayanan gwajin da matsakaici;

F. Zaɓin zaɓi na Sinanci da Ingilishi; raka'a (J / m, KJ / m2, kg-cm / cm, ft-ib / in) za a iya musamman bisa ga abokan ciniki' bukatun.

G. Mini printer da aka gina don buga bayanan gwaji

Ƙayyadaddun bayanai

| Abu | Tasirin Charpy | Izod Tasiri |

| Pendulum makamashi | 1J, 2J, 4J, 5J | 1J, 2.75J, 5.5J |

| Pendulum kwana | 150° | |

| Wuta kwana | 30° | |

| Wuta gaban kwana | 5° | |

| Wuta na baya kwana | 10° | |

| Gudun tasiri | 2.9m/s | 3.5m/s |

| Tasiri ta nisa | mm 221 | mm 335 |

| Ruwa mai cike da radius | R=2mm±0.5mm | R=0.8mm±0.2mm |

|

Rashin makamashi | 0.5J ≤4.0J 1.0J ≤2.0J 2.0J ≤1.0J ≥4.0J≤0.5J | 2.75J ≤0.06J 5.5J ≤0.12J |

|

karfin juyi na pendulum | Pd1J=0.53590Nm Pd2J=1.07180Nm Pd4J=2.14359Nm Pd5J=2.67949Nm | Pd2.75J=1.47372Nm Pd5.5J=2.94744Nm |

| Kwafi | Iyawa. Angle, makamashi, da dai sauransu. | |

| Tushen wutan lantarki | AC220V± 10% 50HZ | |

Ayyukanmu:

Yayin duk tsarin kasuwanci, muna ba da sabis na Siyar da Shawarwari.

FAQ:

Bugu da ƙari, idan na'urar ku ba ta aiki, za ku iya aiko mana da imel ko ku kira mu za mu yi iya ƙoƙarinmu don gano matsalar ta hanyar tattaunawa ko ta hanyar bidiyo idan ya cancanta. Da zarar mun tabbatar da matsalar, za a ba da maganin a cikin sa'o'i 24 zuwa 48.