Kayayyaki

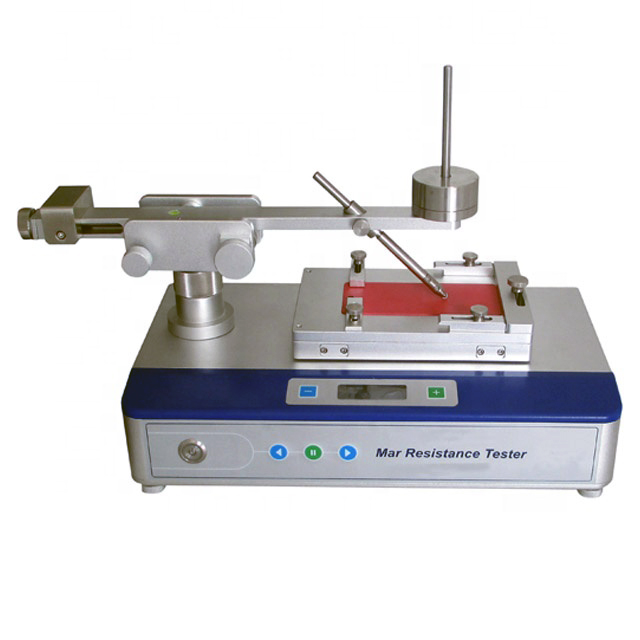

UP-6024 Hanyar zane ta atomatik mai mannewa mai gwadawa

Hanyar zobe ta atomatik mannewa mai gwadawa

Yin amfani da hanyar zobe don kimanta mannewar fim ɗin da substrate na ɗaya daga cikin hanyoyin gargajiya na kasar Sin. Wannan hanyar tana amfani da kayan aikin da aka kera na musamman don ci gaba da zana da'irar diamita iri ɗaya a kan murfin da za a gwada, waɗannan da'irar suna mamaye juna a wani tazara mai nisa, sannan a raba su kashi bakwai gwargwadon girman yanki na ɓangaren da'irar. Kashi 70% na fim ɗin da ba shi da kyau don tantance ma'aunin da ya dace Shi ne sabon na'urar ƙirar zobe ta atomatik na gida, ya dace da daidaitattun GB/T 1720, idan aka kwatanta da sauran injunan gida na gargajiya, yana da halaye masu zuwa:

Duk jikin aluminum oxide, babban matsayi, kyakkyawa, haske

1. Hasken mai nuna alama na musamman zai iya yin hukunci ta atomatik ko allurar ta yanke sutura zuwa substrate, tare da halaye na aiki daidai, dacewa da sauransu.Musamman machining machining allura, don tabbatar da cewa daban-daban allura da kyau daidaitoCikakkun da'irar wutar lantarki, saurin iri ɗaya, ƙarfi akai-akai, sakamakon gwaji tare da haɓakawa mai girma da kwatance.

2. Dandalin zamewa yana dacewa da gwaje-gwaje masu yawa a wurare daban-daban akan allon gwajin guda ɗayaRotary hannu zane, mai matukar dacewa don canza allura da farantin gwaji.

3. Ana amfani da ƙwaya biyu don daidaita tsaftar dunƙulewa, wanda hakan zai sa dandamali ya yi aiki sosai, rage kuskuren da ke haifar da share zaren da kuma sa bayanan su zama daidai.Dandalin aiki yana ɗaukar iyakar jagora biyu, wanda ya fi kwanciyar hankali fiye da jagora ɗaya.Kuna iya komawa wurin farawa tare da maɓalli ɗaya bayan kammala gwajin guda ɗaya

4. Kayan aiki na musamman don zanen allura ya fi dacewa da sauri don haɗuwa da raguwaMadaidaicin machining zaren kula da diamita, sakamakon gwaji ya fi daidai.

5. Daidaitaccen matsayi na wurin farawa da ƙarshen dandalin aiki, tabbatar da tabbatar da cewa kowane gwaji zai iya saduwa da daidaitattun tafiya.

6. Multistage nauyi hade don samun mafi dacewa nauyi nauyi.

7. Ma'aunin nauyi yana jujjuya zane da kansa, wanda ke rage tasirin inertia akan nauyin gwajin lokacin gudu.

Babban sigogi na fasaha

| Juyawa radius | R=5.25mm |

| Tsawon Guoquan | 80mm ku |

| Matsi mara nauyi | 200 g |

| Farmar nauyi | 100g,200g,500g |

| Marubuci | Taurin HRC 45 ~ 50 gami, Tip radius (0.05± 0.01) mm |

| Gudun marubuci | Kusan 90 RPM |

| Substrate bukata | 120 x 50 x 0.2 0.3 mm faranti |

Ayyukanmu:

Yayin duk tsarin kasuwanci, muna ba da sabis na Siyar da Shawarwari.

FAQ:

Bugu da ƙari, idan na'urar ku ba ta aiki, za ku iya aiko mana da imel ko ku kira mu za mu yi iya ƙoƙarinmu don gano matsalar ta hanyar tattaunawa ko ta hanyar bidiyo idan ya cancanta. Da zarar mun tabbatar da matsalar, za a ba da maganin a cikin sa'o'i 24 zuwa 48.