Products

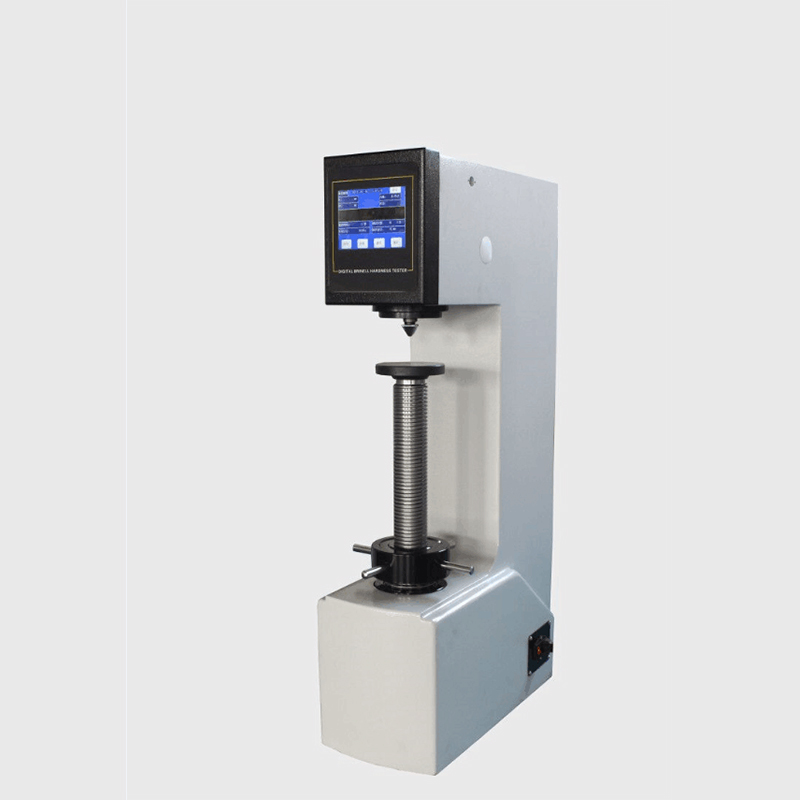

HB-3000/3000B Brinell Hardness Tester

Features

1. The body part of the product is formed at one time by the casting process, and has undergone a long-term aging treatment. Compared with the paneling process, the long-term use of the deformation is extremely small, and it can effectively adapt to various harsh environments;

2. Car baking paint, high-grade paint quality, strong scratch resistance, and still bright as new after many years of use;

3. Solid structure, good rigidity, accurate, reliable, durable, and high test efficiency;

4. The strong and weak electricity phases of the control panel are separated, which avoids mutual interference and the panel breakdown due to excessive current, which improves the safety of operation and the service life of the panel;

5. High-power solid state relay, high power, low power consumption, no contact, no spark, high isolation between control and controlled, and long service life;

6. The high-torque permanent magnet synchronous motor replaces the old-fashioned reducer, so that the machine has low noise and extremely low failure rate;

7. Accuracy conforms to GB/T231.2, ISO6506-2 and American ASTM E10 standards.

Specifications

1.Measuring range: 5-650HBW

2.Test force: 1838.8, 2415.8, 7355.3, 9807, 29421N

3.(187.5, 250, 750, 1000, 3000kgf)

4.Maximum allowable height of the sample: 230mm;

5.Distance from the center of the indenter to the machine wall: 120mm;

6.Dimensions: 700*268*842mm;

7.Power supply: AC220V/50HZ

8.Weight: 140Kg

Gross weight: 210Kg

Main Accessories

● Large flat workbench, small flat workbench, V-shaped workbench: 1 each;

● Steel ball indenter: Φ2.5, Φ5, Φ10 each 1;

● Standard Brinell hardness block: 2