Cov khoom

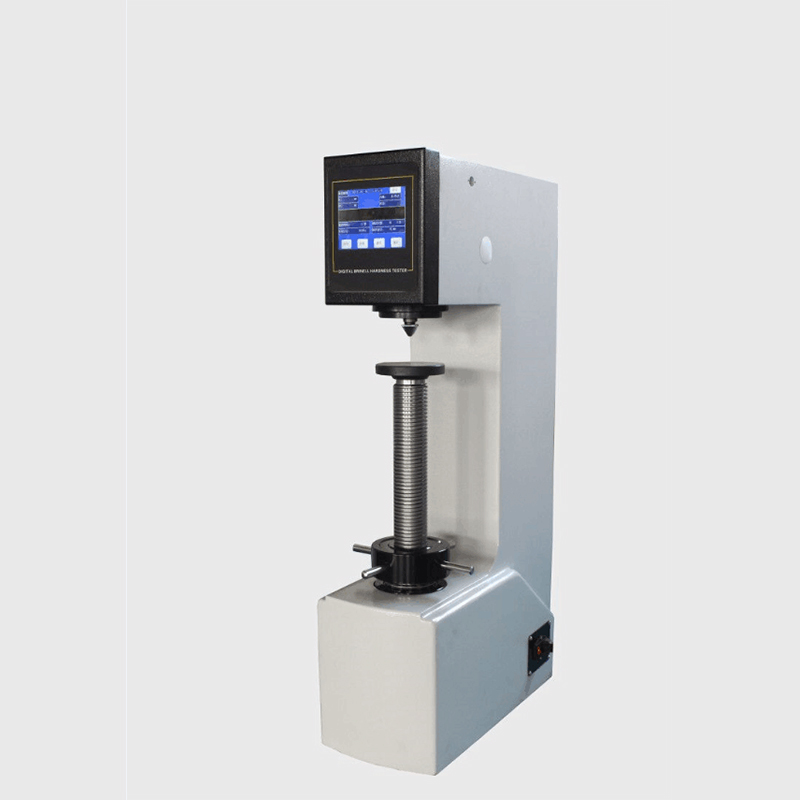

HBE-3000A Electronic Brinell Hardness Tester

Nta

1. Lub cev ib feem ntawm cov khoom yog tsim nyob rau hauv ib lub sij hawm los ntawm cov txheej txheem casting, thiab tau undergone ib tug ntev lub sij hawm kev kho mob. Piv nrog rau cov txheej txheem paneling, kev siv lub sij hawm ntev ntawm qhov deformation yog qhov me me, thiab nws tuaj yeem hloov tau zoo rau ntau qhov chaw hnyav;

2. Lub tsheb ci xim, cov xim qib siab zoo, muaj zog khawb tsis kam, thiab tseem ci ntsa iab li tshiab tom qab siv ntau xyoo;

3. Txais siv hluav taws xob thauj khoom thiab tshem tawm cov kev sim quab yuam, kaw-voj tawm tswv yim los ntawm kev ntsuas siab nrog 5‰ precision, tswj los ntawm ARM32-ntsis ib-chip microcomputer, thiab tuaj yeem them nyiaj rau qhov kev xeem quab yuam hauv kev xeem;

4. Cov qauv tsim, zoo rigidity, raug, txhim khu kev qha, ruaj khov, thiab kev ua haujlwm siab;

5. Tshaj dhau, dhau txoj haujlwm, tsis siv neeg tiv thaiv, hluav taws xob tom qab hluav taws xob, tsis muaj qhov hnyav; tsis siv neeg kuaj txheej txheem, tsis muaj tib neeg kev ua haujlwm yuam kev;

6. Nruab nrog kev ua haujlwm siab stepping lub cev muaj zog rau kev thauj khoom tsis siv neeg thiab tshem tawm, lub suab nrov tsim tawm thaum lub sijhawm ntsuas me me;

7. Kev xaiv CCD cov duab ua haujlwm thiab cov cuab yeej ntsuas video;

8. Qhov tseeb ua tau raws li GB/T231.2, ISO6506-2 thiab American ASTM E10 cov qauv.

Specifications

1. Kev ntsuas ntau: 5-650HBW;

2. Test quab yuam: 612.9, 980.7, 1225.9, 1838.8, 2415.8, 4903.5, 7355.3, 9807, 14710.5, 29421N (62.5, 100, 100, 180, 125, 750, 1000, 1500, 3000kgf);

3. Qhov siab tshaj plaws tso cai qhov siab ntawm tus qauv: 280mm;

4. Kev ncua deb ntawm qhov chaw ntawm lub indenter mus rau lub tshuab phab ntsa: 150mm;

5. Qhov Loj: 700 * 268 * 842mm;

6. Fais fab mov: AC220V / 50Hz

7. Nyhav: 210Kg.

Main accessories

Loj tiaj tus workbench, me me tiaj tus workbench, V-shaped workbench: 1 txhua;

Hlau pob indenter: Φ2.5, Φ5, Φ10 txhua 1;

Hlau pob: 1 txhua ntawm Φ2.5, Φ5, Φ10;

Txheem Brinell hardness thaiv: 2

Peb qhov kev pabcuam:

Thaum lub sij hawm tag nrho cov txheej txheem ua lag luam, peb muab kev pab tswv yim Muag.

FAQ:

Ntxiv mus, Yog tias koj lub tshuab tsis ua haujlwm, koj tuaj yeem xa email rau peb lossis hu rau peb peb yuav sim peb qhov zoo tshaj plaws los nrhiav qhov teeb meem los ntawm peb cov kev sib tham lossis los ntawm kev sib tham video yog tias tsim nyog. Thaum peb tau lees paub qhov teeb meem, cov kev daws teeb meem yuav muab rau hauv 24 txog 48 teev.