Cov khoom

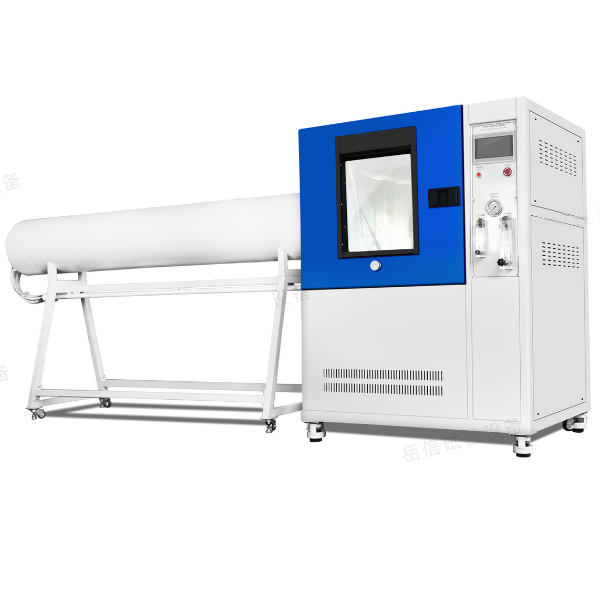

UP-2009 PC Electro-Hydraulic Servo Universal Testing Tshuab

Tus tswv

Tus tswv tsev yog nruab nrog lub tog raj kheej nyob rau hauv tus tswv tsev, qhov chaw kos duab yog nyob saum lub mainframe, thiab qhov chaw compression thiab dabtsi yog khoov qhov chaw nyob nruab nrab ntawm lub ntsiab nqaj thiab lub rooj.

Qhov system kis

Cov nqaj qis nqa lub cev muaj zog los ntawm lub reducer, saw tsav mechanism, pob ntsia hlau tsav, kom ncav cuag stretching, compression chaw hloov.

Hydraulic system

Cov kua dej hydraulic hauv cov roj tank yog tsav los ntawm lub twj tso kua mis siab mus rau hauv cov roj nkag los ntawm lub cev muaj zog, ntws los ntawm lub valve, lub siab siab roj lim, lub siab sib txawv valve pawg, lub servo valve, nkag mus rau hauv lub tog raj kheej (hloov lub tshuab pa nrog qhov sib txawv, yog li tsis paub txog cov roj to phenomenon) Lub khoos phis tawj xa tawm lub servo valve tswj kev taw qhia rau lub tog raj kheej. yog li tswj cov dej ntws mus rau hauv lub tog raj kheej, paub txog qhov kev ntsuas qhov nrawm tas li, qhov kev hloov pauv tsis tu ncua thiab lwm yam ntawm kev tswj.

Tswj System

Taw qhia rau cov yam ntxwv

1, kev txhawb nqa rau ncab, compression, txiav, khoov thiab lwm yam kev xeem;

2, txhawb kev qhib kho qhov kev xeem, kho cov qauv thiab kho cov kauj ruam, thiab txhawb nqa kev xeem, cov qauv thiab cov txheej txheem;

3, Txhawb kev ntsuas ntsuas kev hloov kho;

4, siv qhib EXCEL daim ntawv qhia, txhawb cov neeg siv kev cai qhia hom;

5, cov lus nug luam tawm cov txiaj ntsig tau hloov pauv thiab yooj yim los txhawb kev luam ntawv ntawm ntau cov qauv, kev cai txheeb xyuas cov khoom luam tawm;

6, Qhov kev zov me nyuam los nrog kev ntsuam xyuas muaj zog muaj nuj nqi;

7, kev pab txhawb nqa hierarchical tswj theem (tus thawj tswj hwm, tus tsav) tswj cov neeg siv khoom;

Software Description

1, Lub ntsiab interface teeb yog ntau lub luag haujlwm, lub ntsiab interface ntawm qhov kev zov me nyuam suav nrog: thaj tsam kab ke, thaj chaw cuab yeej, vaj huam sib luag, ceev zaub vaj huam sib luag, thaj chaw ntsuas ntsuas, thaj tsam txheej txheem, ntau qhov nkhaus nkhaus, thaj chaw ua haujlwm, cov ntaub ntawv xeem cheeb tsam.

2, Curve rendering: Lub software system muab ib tug nplua nuj xeem nkhaus zaub. Xws li kev quab yuam - hloov nkhaus, quab yuam - deformation nkhaus, kev nyuaj siab - hloov pauv nkhaus, kev ntxhov siab - deformation nkhaus, quab yuam - lub sij hawm nkhaus, deformation - lub sij hawm nkhaus.

3, Cov ntaub ntawv ua haujlwm tsom xam interface: raws li cov neeg siv yuav tsum tau txais, ReH, ReL, Fm, Rp0.2, Rt0.5, Rm, E thiab lwm yam kev xeem.

4, Test daim ntawv qhia interface: lub software operating system muab ib tug haib daim ntawv qhia ua hauj lwm, cov neeg muas zaub tau luam lawv tus kheej xav tau kev pab raws li lawv xav tau kev xeem daim ntawv qhia. Cov ntaub ntawv xeem tuaj yeem khaws cia, luam tawm, thiab tshuaj xyuas.

5, Kev tiv thaiv kev nyab xeeb

Thaum qhov kev xeem quab yuam tshaj 3% ntawm qhov siab tshaj plaws kev xeem quab yuam, kev tiv thaiv overload, twj tso kua mis lub cev muaj zog kaw.

Thaum lub piston nce mus rau qhov siab tshaj plaws txoj hauj lwm, kev tiv thaiv mob stroke, lub twj tso kua mis lub cev muaj zog nres.

Main Specifications

A) Style: Microcomputer tswj, ob kab kem hom

B) Kev sim siab tshaj plaws: 300KN;

C) qhov kev daws teeb meem tsawg kawg nkaus ntawm qhov kev xeem: 0.01N;

D) Kev ntsuas qhov tseeb: 4% -100% FS

E) qhov tseeb ntawm kev xeem quab yuam; zoo tshaj ± 1%

F) Kev daws teeb meem: 0.01mm;

G) Kev ntsuas qhov tseeb: 0.01

H) Stretch mus ncig: 600mm

I) Compression stroke: 600 hli

J) Piston stroke: 150 min

K) Kev khiav ceev tswj qhov tseeb: ± 1% (feem ntau)

L) Tester qib: 1 (zoo tib yam) / 0.5 qib

M) Lub puab tsaig puag ncig tuav lub taub: Φ6-Φ26mm

N) Flat specimen puab tsaig tuav lub thickness: 0-15mm

O) Tester loj: 450 * 660 * 2520mm

P) Qhov siab tshaj plaws tiaj tus qauv clamping dav: φ160mm

Q) Siab phaj loj: φ160mm

R) Bending test Qhov siab tshaj plaws ntawm ob lub ntsiab lus: 450 mm

S) Khoov yob dav: 120mm

T) Khoov dov txoj kab uas hla: Φ30 mm

H) Qhov siab tshaj plaws piston txav ceev: 50mm / min

I) txoj kev clamping hydraulic clamping

J) Mainframe qhov ntev: 720 × 580 × 1950 mm

k) Ntsuas txee loj: 1000 × 700 × 1400mm

l) Fais fab mov: 220V, 50Hz

m) Tester hnyav: 2100kg

Peb qhov kev pabcuam:

Thaum lub sij hawm tag nrho cov txheej txheem ua lag luam, peb muab kev pab tswv yim Muag.

FAQ:

Ntxiv mus, Yog tias koj lub tshuab tsis ua haujlwm, koj tuaj yeem xa email rau peb lossis hu rau peb peb yuav sim peb qhov zoo tshaj plaws los nrhiav qhov teeb meem los ntawm peb cov kev sib tham lossis los ntawm kev sib tham video yog tias tsim nyog. Thaum peb tau lees paub qhov teeb meem, cov kev daws teeb meem yuav muab rau hauv 24 txog 48 teev.