As an important part of material mechanical properties testing, tensile testing plays an important role in industrial manufacturing, material research and development, etc. However, some common errors will have a huge impact on the accuracy of test results. Have you noticed these details?

1.The force sensor does not match the test requirements:

The force sensor is a key component in tensile testing, and choosing the right force sensor is crucial. Some common mistakes include: not calibrating the force sensor, using a force sensor with an inappropriate range, and aging the force sensor to cause failure.

Solution:

The following factors should be considered when selecting the most suitable force sensor according to the sample:

1. Force sensor range:

Determine the required force sensor range based on the maximum and minimum force values of the results required for your test sample. For example, for plastic samples, if both tensile strength and modulus need to be measured, it is necessary to comprehensively consider the force range of these two results to select the appropriate force sensor.

2. Accuracy and accuracy range:

The common accuracy levels of force sensors are 0.5 and 1. Taking 0.5 as an example, it usually means that the maximum error allowed by the measurement system is within ±0.5% of the indicated value, not ±0.5% of the full scale. It is important to distinguish this.

For example, for a 100N force sensor, when measuring a 1N force value, ±0.5% of the indicated value is ±0.005N error, while ±0.5% of the full scale is ±0.5N error.

Having accuracy does not mean that the entire range is of the same accuracy. There must be a lower limit. At this time, it depends on the accuracy range.

Taking different test systems as an example, the UP2001&UP-2003 series force sensors can meet 0.5 level accuracy from full scale to 1/1000 of full scale.

The fixture is not suitable or the operation is wrong:

The fixture is the medium that connects the force sensor and the specimen. How to choose the fixture will directly affect the accuracy and reliability of the tensile test. From the test appearance, the main problems caused by using inappropriate fixtures or wrong operation are slipping or broken jaws.

Slipping:

The most obvious slipping of the specimen is the specimen coming out of the fixture or the abnormal force fluctuation of the curve. In addition, it can also be judged by marking the mark near the clamping position before the test to see whether the mark line is far away from the clamping surface, or whether there is a drag mark on the tooth mark of the specimen clamping position.

Solution:

When slippage is found, first confirm whether the manual clamp is tightened when clamping the sample, whether the air pressure of the pneumatic clamp is large enough, and whether the clamping length of the sample is sufficient.

If there is no problem with the operation, consider whether the clamp or clamp face selection is appropriate. For example, metal plates should be tested with serrated clamp faces instead of smooth clamp faces, and rubber with large deformation should use self-locking or pneumatic clamps instead of manual flat-push clamps.

Breaking jaws:

Solution:

The specimen jaws break, as the name implies, break at the clamping point. Similar to slipping, it is necessary to confirm whether the clamping pressure on the specimen is too large, whether the clamp or jaw surface is selected appropriately, etc.

For example, when conducting a rope tensile test, excessive air pressure will cause the specimen to break at the jaws, resulting in low strength and elongation; for film testing, rubber-coated jaws or wire-contact jaws should be used instead of serrated jaws to avoid damaging the specimen and causing premature failure of the film.

3. Load chain misalignment:

The alignment of the load chain can be simply understood as whether the center lines of the force sensor, fixture, adapter and specimen are in a straight line. In tensile testing, if the alignment of the load chain is not good, the test sample will be subjected to additional deflection force during loading, resulting in uneven force and affecting the authenticity of the test results.

Solution:

Before the test begins, the centering of the load chain other than the specimen should be checked and adjusted. Each time the specimen is clamped, pay attention to the consistency between the specimen’s geometric center and the loading axis of the load chain. You can choose a clamping width close to the specimen’s clamping width, or install a specimen centering device to facilitate positioning and improve clamping repeatability.

4.Incorrect selection and operation of strain sources:

Materials will deform during tensile testing. Common errors in strain (deformation) measurement include incorrect selection of strain measurement source, inappropriate selection of extensometer, improper installation of extensometer, inaccurate calibration, etc.

Solution:

The selection of strain source is based on the geometry of the specimen, the amount of deformation, and the required test results.

For example, if you want to measure the modulus of plastics and metals, the use of beam displacement measurement will result in a low modulus result. At this time, you need to consider the specimen gauge length and the required stroke to select a suitable extensometer.

For long strips of foil, ropes and other specimens, the beam displacement can be used to measure their elongation. Whether using a beam or an extensometer, it is very important to ensure that the frame and extensometer are metered before conducting a tensile test.

At the same time, ensure that the extensometer is properly installed. It should not be too loose, causing the extensometer to slip during the test, or too tight, causing the specimen to break at the extensometer blade.

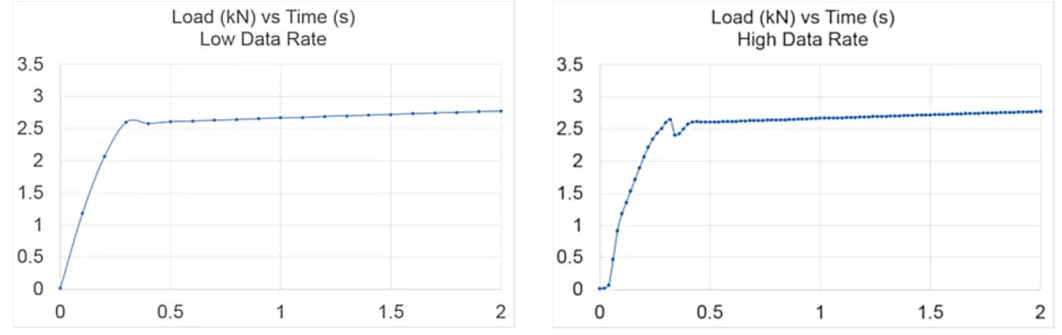

5.Inappropriate sampling frequency:

The data sampling frequency is often overlooked. A low sampling frequency may cause the loss of key test data and affect the authenticity of the results. For example, if the true maximum force is not collected, the maximum force result will be low. If the sampling frequency is too high, it will be over-sampled, resulting in data redundancy.

Solution:

Select the appropriate sampling frequency based on the test requirements and material properties. A general rule is to use a 50Hz sampling frequency. However, for rapidly changing values, a higher sampling frequency should be used to record data.

6. Dimension measurement errors:

Dimension measurement errors include not measuring the actual sample size, measuring position errors, measuring tool errors, and dimension input errors.

Solution:

When testing, the standard specimen size should not be used directly, but actual measurement should be performed, otherwise the stress may be too low or too high.

Different specimen types and size ranges require different test contact pressures and accuracy of the dimension measuring device.

A specimen often needs to measure the dimensions of multiple locations to average or take the minimum value. Pay more attention to the recording, calculation and input process to avoid mistakes. It is recommended to use an automatic dimension measuring device, and the measured dimensions are automatically input into the software and statistically calculated to avoid operating errors and improve test efficiency.

7. Software setting error:

Just because the hardware is fine does not mean the final result is correct. The relevant standards for various materials will have specific definitions and test instructions for the test results.

The settings in the software should be based on these definitions and test process instructions, such as preloading, test rate, selection of calculation type and specific parameter settings.

In addition to the above common errors related to the test system, specimen preparation, test environment, etc. also have an important impact on tensile testing and need to be paid attention to.

Post time: Oct-26-2024