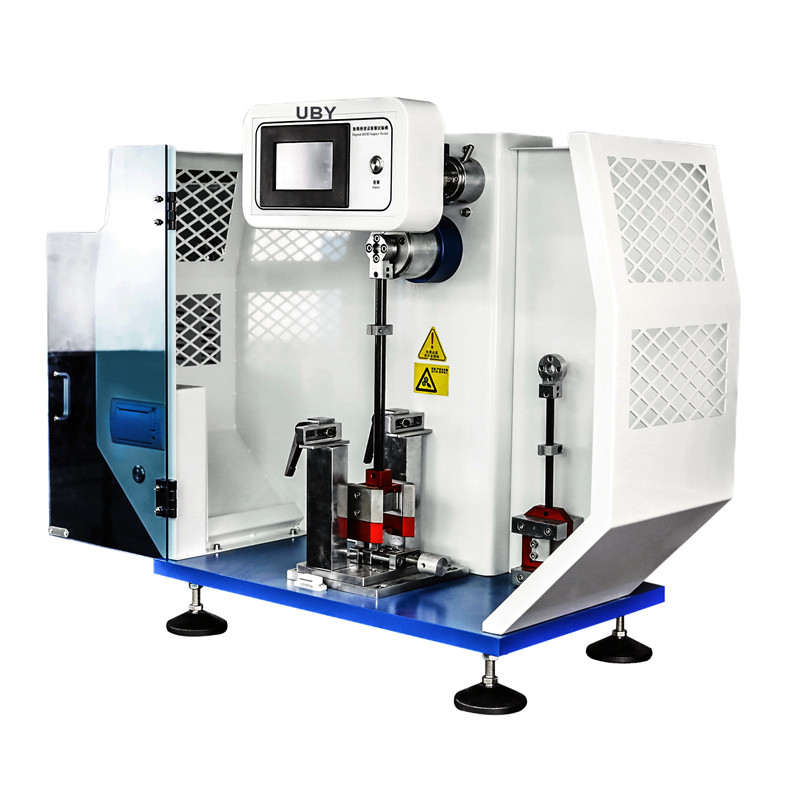

Impact testing is a critical process for evaluating materials, especially non-metallic materials, to determine their ability to withstand sudden forces or impacts. To carry out this important test, a drop impact testing machine, also known as a drop weight testing machine, is often used. This type of digital display simply supported beam impact testing machine is specially used to measure the impact toughness of various non-metallic materials, including hard plastics, reinforced nylon, glass fiber, ceramics, cast stone, insulating materials, etc.

The working principle of the drop impact testing machine is to drop a heavy object from a specified height onto the test sample, simulating the impact that the material may suffer in real life. This allows an assessment of the material's ability to absorb energy and resist fracture under sudden loading conditions. The machine accurately measures the energy absorbed by a sample during impact, providing valuable data for material characterization and quality control.

In the chemical industry, scientific research institutes, colleges and universities, and quality inspection departments, drop impact testing machines are indispensable testing equipment. It enables researchers, engineers and quality control professionals to evaluate the impact resistance of non-metallic materials, ensuring they meet the standards and specifications required for their intended application.

The versatility of the drop impact test machine it suitable for a wide range of materials, making it ideal for a variety of industries. Whether evaluating the impact toughness of rigid plastics used in consumer products, evaluating the durability of fiberglass components in construction, or testing the resiliency of insulating materials in electrical applications, drop impact testing machines can provide valuable insights into the performance of non-metallic materials. under impact load.

The precise and reliable nature of drop impact testing machines makes them an important tool for R&D activities. By understanding how materials respond to sudden impacts, engineers and scientists can make informed decisions about material selection, design optimization, and product improvements. This ultimately helps develop safer and more durable non-metallic materials for a wide range of applications.

When considering impact testing, it is essential to select a drop impact testing machine that complies with required industry standards and specifications. The digital Charpy impact tester mentioned earlier is designed to meet these standards, ensuring test results are accurate and repeatable. In addition, modern drop impact testing machines are often equipped with advanced digital control and data acquisition systems to further improve the accuracy and efficiency of the testing process.

Post time: Jun-27-2024