Sechikamu chakakosha chekuyedzwa kwezvinhu zvemuchina, kuyedza kusimba kunoita basa rakakosha mukugadzira maindasitiri, kutsvagisa zvinhu uye kusimudzira, nezvimwe zvakadaro, zvimwe zvikanganiso zvakajairika zvichave nemhedzisiro yakakura pakurongeka kwemhedzisiro yebvunzo. Waona mashoko aya here?

1.Iyo simba sensor haienderane nezvinodiwa zvekuedza:

Iyo simba sensor chinhu chakakosha mukuyedzwa kwekumanikidza, uye kusarudza iyo chaiyo simba sensor kwakakosha. Zvimwe zvikanganiso zvakajairika zvinosanganisira: kusayera iyo simba sensor, kushandisa simba sensor ine isina kufanira renji, uye kuchembera iyo simba sensor kukonzeresa kutadza.

Solution:

Izvi zvinotevera zvinhu zvinofanirwa kutariswa pakusarudza iyo yakanyanya kukodzera simba sensor zvinoenderana nemuenzaniso:

1. Simba sensor range:

Sarudza iyo inodiwa simba sensor renji zvichienderana nehupamhi uye hudiki simba kukosha kwemhedzisiro inodiwa kune yako bvunzo sampuli. Semuyenzaniso, kune epurasitiki samples, kana ese ari maviri ekusimba kwesimba uye modulus zvinoda kuyerwa, zvinodikanwa kunyatso funga nezve simba remhando yezviviri izvi mhedzisiro kusarudza yakakodzera simba sensor.

2. Kururama uye kurongeka kwemhando:

Izvo zvakajairika kururamisa mazinga emasimba masimba ndeye 0.5 uye 1. Kutora 0.5 semuenzaniso, zvinowanzoreva kuti kukanganisa kwakanyanya kunobvumirwa nechiyero chekuyera chiri mukati ± 0.5% yehuwandu hunoratidzwa, kwete ± 0.5% yechiyero chakazara. Zvakakosha kusiyanisa izvi.

Semuenzaniso, kune 100N simba sensor, pakuyera kukosha kwe1N simba, ± 0.5% yehuwandu hunoratidzwa ndeye ± 0.005N kukanganisa, nepo ± 0.5% yechiyero chakazara ± 0.5N kukanganisa.

Kuva nekururama hakurevi kuti nhevedzano yacho yose ndeyekururama kwakafanana. Panofanira kuva nemuganhu wakaderera. Panguva ino, zvinoenderana nehuwandu hwekururama.

Tichitora masisitimu ebvunzo akasiyana semuenzaniso, iyo UP2001&UP-2003 yakatevedzana simba masensa anogona kusangana ne0.5 nhanho yechokwadi kubva pachiyero chakazara kusvika 1/1000 chechiyero chakazara.

Iyo gadziriso haina kukodzera kana kushanda kwakashata:

Iyo gadziriso ndiyo yepakati inobatanidza iyo simba sensor uye specimen. Maitiro ekusarudza gadziriso anozokanganisa zvakananga kurongeka uye kuvimbika kweiyo tensile bvunzo. Kubva pakuonekwa kwekuyedzwa, matambudziko makuru anokonzerwa nekushandisa zvigadziriso zvisina kufanira kana mashandiro asina kunaka ari kutsvedza kana kutyoka shaya.

Kutsvedza:

Kutsvedza kuri pachena kwechienzaniso ndicho chifananidzo chinobuda kunze kwechigadziriso kana kushanduka kwesimba kusingaite kwe curve. Pamusoro pezvo, inogona zvakare kutongwa nekumaka mucherechedzo padhuze nenzvimbo yekusungirira isati yaedzwa kuti uone kana mutsetse wechiratidzo uri kure nepanosungirira, kana kuti pane chiratidzo chekukwevera pane zino chiratidzo cheiyo specimen clamping chinzvimbo.

Solution:

Kana kutsvedza kwawanikwa, tanga wasimbisa kuti chivharo chemaoko chakasimbiswa kana uchisunga sampuli, kana mhepo yemhepo yepneumatic clamp yakakura zvakakwana, uye kana kureba kwekusunga kwemuenzaniso kwakakwana.

Kana pasina dambudziko nekuvhiya, funga kana iyo clamp kana clamp kusarudzwa kwechiso kwakakodzera. Semuyenzaniso, marata esimbi anofanirwa kuyedzwa aine zviso zvakasungirirwa pachinzvimbo chezviso zvakatsetseka, uye rabha ine deformation yakakura inofanira kushandisa yekuzvivharira kana pneumatic clamps pachinzvimbo chemanual flat-push clamps.

Kutyoka shaya:

Solution:

Iyo yemuenzaniso shaya inotyoka, sekureva kwazvinoreva, tyora pane clamping point. Zvakafanana nekutsvedza, zvinodikanwa kusimbisa kana iyo yekumanikidza yekumanikidza pamuenzaniso yakakurisa, ingave iyo clamp kana shaya nzvimbo yakasarudzwa zvakakodzera, nezvimwe.

Semuenzaniso, kana uchiitisa tambo yekumanikidza bvunzo, yakawandisa mhepo kumanikidza kuchaita kuti mufananidzo utyoke pashaya, zvichikonzera kuderera kwesimba uye kureba; pakuongorora firimu, shaya dzakavharwa nerabha kana waya-dzinobata shaya dzinofanira kushandiswa panzvimbo yeshaya dzakatsemuka kudzivirira kukuvadza sampuli uye kukonzera kukundikana kwefirimu nguva isati yakwana.

3. Load cheni kusarongeka:

Kurongeka kweketani yekutakura kunogona kungonzwisiswa sekuti mitsetse yepakati yesimba sensor, fixture, adapta uye specimen iri mumutsara wakatwasuka. Mukuyedzwa kwekunetseka, kana kurongeka kweketani yemutoro isina kunaka, sampu yekuyedza ichaiswa kune yakawedzera deflection simba panguva yekurodha, zvichikonzera kusaenzana kwesimba uye kukanganisa chokwadi chemhedzisiro yebvunzo.

Solution:

Muedzo usati watanga, pakati pecheni yekutakura kunze kwemuenzaniso inofanira kuongororwa uye kugadziriswa. Nguva imwe neimwe iyo muenzaniso inosungirirwa, teerera kune kuenderana pakati peiyo specimen's geometric centre uye yekurodha axis yecheni yekutakura. Iwe unogona kusarudza hupamhi hwekusunga padhuze nehupamhi hwekurovedzera kwemuenzaniso, kana kuisa specimen centering mudziyo kufambisa chinzvimbo uye kunatsiridza clamping kudzokorora.

4.Kusarudzika kusarudzwa uye kushanda kwematambudziko masosi:

Zvishandiso zvinokanganisa panguva yekuyedzwa kwekunetseka. Zvikanganiso zvakajairika mukunetseka (deformation) kuyerwa kunosanganisira kusarudzwa kwakashata kweiyo strain yekuyera sosi, kusarudzwa kusina kufanira kweextensometer, kuiswa kwakashata kweextensometer, kuenzana kusiri iko, nezvimwe.

Solution:

Kusarudzwa kweiyo strain sosi kunobva pane geometry yemuenzaniso, huwandu hwe deformation, uye inodiwa bvunzo mhinduro.

Semuenzaniso, kana iwe uchida kuyera modulus yemapurasitiki nesimbi, kushandiswa kwebeam displacement kuyerwa kunoguma yakaderera modulus mhedzisiro. Panguva ino, unofanirwa kufunga nezvehurefu hwejeji yemuenzaniso uye sitiroko inodiwa kuti usarudze yakakodzera extensometer.

Kune mitsetse yakareba yefoiri, tambo uye zvimwe zvienzaniso, danda rekuchinjisa rinogona kushandiswa kuyera kureba kwavo. Kungave uchishandisa danda kana extensometer, zvakakosha kuti uve nechokwadi chekuti furemu uye extensometer zvakamisikidzwa usati waita bvunzo yekumanikidza.

Panguva imwecheteyo, ita shuwa kuti extensometer yakaiswa zvakanaka. Iyo haifanirwe kuve yakasununguka zvakanyanya, zvichiita kuti extensometer itsvedze panguva yekuyedzwa, kana kuti yakanyanya kusimba, zvichiita kuti mufananidzo utyoke pane extensometer blade.

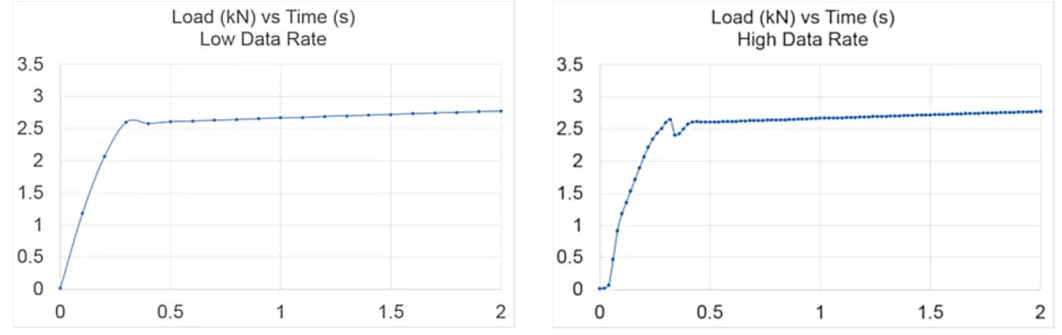

5.Inappropriate sampling frequency:

Iyo data sampling frequency inowanzo furatirwa. A low sampling frequency inogona kukonzera kurasikirwa kwekiyi yekuyedza data uye kukanganisa huchokwadi hwemhedzisiro. Semuenzaniso, kana simba rechokwadi repamusoro risina kuunganidzwa, simba guru rinoguma richave rakaderera. Kana iyo sampling frequency yakawandisa, ichave yakawandisa-sampled, zvichikonzera dhata redundancy.

Solution:

Sarudza iyo yakakodzera sampling frequency zvichienderana nezvinodiwa bvunzo uye zvinhu zvenyama. Mutemo wakajairika kushandisa 50Hz sampling frequency. Nekudaro, pakuchinja nekukurumidza kukosha, yakakwira sampling frequency inofanirwa kushandiswa kurekodha data.

6. Dimension yekuyera kukanganisa:

Kukanganisa kuyerwa kweDimension zvinosanganisira kusayera saizi chaiyo yemuenzaniso, kukanganisa nzvimbo yekuyeresa, mhosho dzematurusi ekuyeresa, uye zvikanganiso zvekupinza mativi.

Solution:

Paunenge uchiyedzwa, saizi yemuenzaniso yakajairika haifanirwe kushandiswa zvakananga, asi kuyerwa chaiko kunofanirwa kuitwa, zvikasadaro kushushikana kunogona kunge kwakadzikira kana kwakanyanya.

Mhando dzakasiyana siyana uye saizi masanzi zvinoda akasiyana bvunzo madhindindi uye huchokwadi hweiyo dimension yekuyeresa mudziyo.

Sayenzi inowanzoda kuyera hukuru hwenzvimbo dzakawanda kuavhareji kana kutora kukosha kushoma. Teerera zvakanyanya kune kurekodha, kuverenga uye kuisa maitiro kuti udzivise kukanganisa. Zvinokurudzirwa kushandisa otomatiki dimension yekuyeresa mudziyo, uye zviyero zvakayerwa zvinoiswa otomatiki musoftware uye nekuverengerwa kuverengerwa kudzivirira kukanganisa kushanda uye kugadzirisa bvunzo.

7. Kukanganisa kuseta software:

Nekuda kwekuti Hardware yakanaka hazvireve kuti mhedzisiro ndeyechokwadi. Mayero akakodzera ezvishandiso akasiyana achave netsanangudzo dzakananga uye mirairo yebvunzo yemhedzisiro yebvunzo.

Izvo zvigadziriso zviri musoftware zvinofanirwa kunge zvichibva pane idzi tsananguro uye bvunzo maitiro mirairo, senge preloading, chiyero chekuyedza, kusarudzwa kwerudzi rwekuverenga uye yakatarwa parameter marongero.

Pamusoro pezvikanganiso zvakajairika zvine chekuita neiyo test system, gadziriro yemuenzaniso, nharaunda yekuyedza, nezvimwe zvinewo zvakakosha pakuyedzwa kwekusimba uye zvinoda kutariswa.

Nguva yekutumira: Oct-26-2024