Products

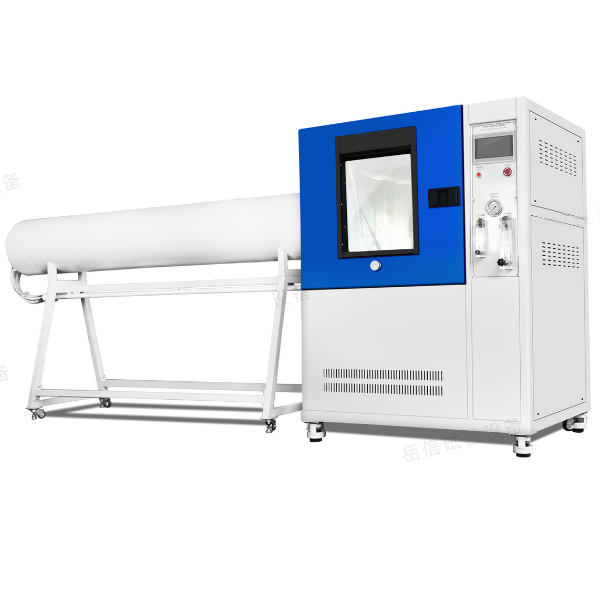

UP-2009 PC Electro-Hydraulic Servo Universal Testing Machine

Host

Iyo saiti inoshongedzerwa necylinder pasi pemugadziri, nzvimbo yekudhirowa iri pamusoro peiyo mainframe, uye yekumanikidza uye yekukotama nzvimbo yekuyedza iri pakati pedanda guru netafura.

Transmission system

Iyo yakaderera danda inosimudza mota neinodzikisira, chain drive mechanism, bhora screw drive, kuwana kutambanudza, compression nzvimbo kugadzirisa.

Hydraulic system

Iyo hydraulic fluid mutangi yemafuta inofambiswa nepamusoro-kudzvanywa pombi ichipinda mugero remafuta kuburikidza nemota, inoyerera nepakati chekivhavha, iyo yakanyanya kudzvanywa mafuta sefa, iyo yekumanikidza musiyano wevharuvhu boka, iyo servo valve, inopinda mucylinder (tsiva yakajairika muchina nechisimbiso chegap, saka haizive iyo mafuta inodonha chiitiko) Iyo komputa inotumira iyo servo chiratidzo chekuvhura, iyo komputa inotumira iyo servo nzira yekudzora uye inovhura iyo yekuvhura. vharafu, nokudaro inodzora kuyerera ichipinda mucylinder, inoona iyo inogara ichimhanya bvunzo simba, inogara ichimhanya kufambisa uye zvichingodaro kutonga.

Kudzora System

Nhanganyaya yezvimiro

1, tsigiro yekutambanudza, kudzvanya, kucheka, kukotama uye mimwe miedzo;

2, tsigira yakavhurika editing bvunzo, gadzirisa akajairwa uye gadzirisa matanho, uye tsigira kunze bvunzo bvunzo, zviyero uye maitiro;

3, Tsigiro yekuyedza parameter kugadzirisa;

4, shandisa yakavhurika EXCEL mushumo fomu, tsigira mushandisi tsika mushumo fomati;

5,mubvunzo kudhinda bvunzo mhinduro inochinjika uye yakanakira kutsigira kudhindwa kwemasamples akawanda, tsika yekuronga zvakadhinda zvinhu;

6, Chirongwa chinouya chine simba rekuongorora bvunzo basa;

7, chirongwa chinotsigira hierarchical management level (mutongi, mutyairi) mushandisi manejimendi masimba;

Tsanangudzo yeSoftware

1,Iyo huru interface seti ndeye-multi-function, iyo huru interface yechirongwa inosanganisira: system menyu nharaunda, chishandiso nzvimbo, yekuratidzira pani, yekumhanyisa kuratidza pani, bvunzo parameter nzvimbo, bvunzo process nharaunda, yakawanda-curve curve nzvimbo, mhedzisiro yekugadziriswa nzvimbo, bvunzo yeruzivo Nzvimbo.

2, Curve rendering: Iyo software system inopa yakapfuma yekuyedza curve kuratidza. Zvakadai sechisimba - kuchinjika curve, simba - deformation curve, kushushikana - kutama curve, kushushikana - deformation curve, simba - nguva curve, deformation - nguva curve.

3, Dhata yekugadzirisa yekuongorora interface: zvinoenderana nezvinodiwa nemushandisi zvakangowanikwa, ReH, ReL, Fm, Rp0.2, Rt0.5, Rm, E uye mamwe mhedzisiro yebvunzo.

4, Test report interface: iyo software inoshanda sisitimu inopa ane simba mushumo wekugadzirisa mabasa, vatengi vanogona kudhinda zvavanoda ivo maererano nezvavanoda bvunzo mushumo. Yedza data inogona kuchengetwa, kudhindwa, uye kuongororwa.

5, Kuchengetedza kuchengetedza mudziyo

Kana simba rekuyedza richipfuura 3% yesimba repamusoro rekuyedza, kudzivirira kuwanda, kuvharika kwepombi.

Kana piston ichikwira kumusoro kwemuganho chinzvimbo, kudzivirira sitiroko, mota yepombi inomira.

Main Specifications

A) Chimiro: Microcomputer kutonga, kaviri column mhando

B) Maximum test simba: 300KN;

C) kugadziriswa kudiki kwesimba rekuyedza: 0.01N;

D) Yakarurama kuyerwa siyana: 4% -100% FS

E) kunyatsoita simba rekuedza; zviri nani pane ± 1%

F) Displacement kugadziriswa: 0.01mm;

G) Displacement kuyerwa kwechiyero: 0.01

H) Kutambanudza kufamba: 600mm

I) Kutsikirira sitiroko: 600mm

J) Piston sitiroko: 150min

K) Displacement kumhanya kudzora kurongeka: ± 1% (yakajairika)

L) Tester level: 1 (yakajairika) /0.5 nhanho

M) Round specimen shaya dzinobata dhayamita: Φ6-Φ26mm

N) Flat specimen shaya dzinobata ukobvu: 0-15mm

O) Tester saizi: 450 * 660 * 2520mm

P) Maximum flat flat specimen clamping width: φ160mm

Q) Kudzvanywa ndiro saizi: φ160mm

R) Kubhenda bvunzo Yakakura kureba pakati pemapoinzi maviri: 450 mm

S) Bending mupumburu upamhi: 120mm

T) Bend rolling dhayamita:Φ30 mm

H) Yepamusoro piston kufamba kumhanya: 50mm / min

I) clamping nzira hydraulic clamping

J) Mainframe zviyero 720 × 580 × 1950 mm

k) Gauge cabinet size: 1000×700×1400mm

l) Simba rekushandisa: 220V, 50Hz

m) Tester uremu: 2100kg

Basa redu:

Munguva yese yebhizinesi maitiro, isu tinopa Consultative Kutengesa sevhisi.

FAQ:

Uyezve, Kana muchina wako usingashande, unogona kutitumira e-mail kana kutifonera isu tichaedza nepatinogona napo kuti tiwane dambudziko kuburikidza nehurukuro yedu kana nevhidhiyo chat kana zvichidikanwa. Kana tangosimbisa dambudziko, mhinduro ichapihwa mukati memaawa makumi maviri nemana kusvika makumi mana nemasere.