Lihlahisoa

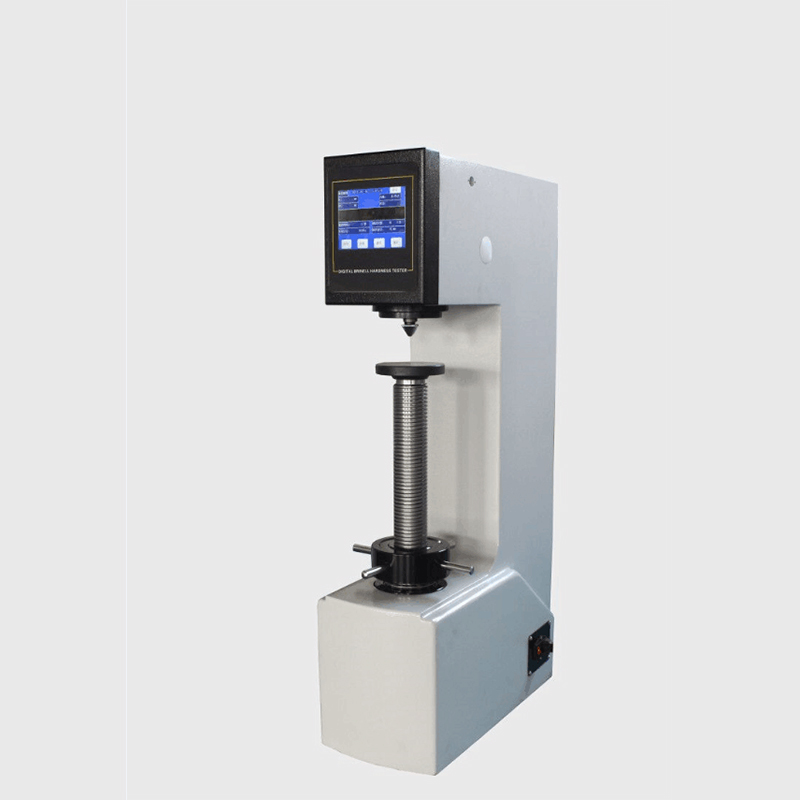

HB-3000T Brinell Hardness Tester

Sebaka sa Kopo

Boikemisetso ba ho thatafala ha Brinell ea ferrous, non-ferrous and bearing alloy materials.

Tse kang cemented carbide, carburized steel steel, surface hardened steel, hard cast steel, aluminium alloy, copper alloy, malleable casting, tšepe e bonolo, tšepe e timang le e halefileng, tšepe e halikiloeng, tšepe e nang le marako, joalo-joalo.

Likaroloana

1. Pente ea ho baka koloi, boleng ba pente ea boemo bo holimo, bokhoni bo matla ba ho thibela ho opa, 'me e ntse e khanya e le ncha ka mor'a lilemo tse ngata tsa tšebeliso;

2. Mekhahlelo ea motlakase e matla le e fokolang ea phanele ea taolo e arohane, e qobang ho kena-kenana le ho senyeha ha phanele ka lebaka la hona joale ho feteletseng, le ho ntlafatsa polokeho ea ts'ebetso le bophelo ba tšebeletso ea phanele;

3. Matla a phahameng a matla a matla a matla a matla, matla a phahameng, tšebeliso ea matla a fokolang, ho se kopane, ha ho na tlhase, ho itšehla thajana ho phahameng pakeng tsa taolo le taolo, le bophelo bo bolelele ba tšebeletso;

4. Sebopeho se tiileng, ho tiea hantle, ho nepahala, ho tšepahala, ho tšoarella, le katleho e phahameng ea liteko;

5. Overload, over-position, automatic protection, electronic afterburner, ha ho boima;

6. Ts'ebetso ea teko e iketsetsa, 'me ha ho na phoso ea ts'ebetso ea motho;

7. Motlakase o phahameng oa torque o sa feleng oa magnet synchronous motor o nkela mochine o fokotsang oa khale, e le hore mochine o be le lerata le tlaase le tekanyo e tlaase haholo ea ho hlōleha;

8. Ho nepahala ho lumellana le litekanyetso tsa GB/T231.2, ISO6506-2 le American ASTM E10.

Tekheniki Parameters

1. Lethathamo la ho lekanya: 5-650HBW

2. Matla a teko: 1838.8, 2415.8, 7355.3, 9807, 29421N

(187.5, 250, 750, 1000, 3000kgf)

3. Bophahamo bo phahameng bo lumelletsoeng ba sampuli: 500mm;

4. Sebaka ho tloha bohareng ba inndenter ho ea leboteng la mochine: 180mm;

5. Litekanyo: 780 * 460 * 1640mm;

6. Phepelo ea matla: AC220V/50Hz

7. Boima: 400Kg.

Tlhophiso e tloaelehileng

● Setulo se seholo se bataletseng, se senyenyane se sephara se sephara, se nang le sebopeho sa V: 1 ka 'ngoe;

● Tafole e nang le seqha bakeng sa ho hlahloba liliba le liphaephe tsa tšepe, bophara bo ka hare ba mosebetsi o lokelang ho lekoa ke Φ70 ho Φ350mm, 'me botenya ba lerako la workpiece e lokelang ho lekoa ke ≤42mm; (e ka boela ea etsoa ho latela boholo ba sehlahisoa)

● Indenter ea bolo ea tšepe: Φ2.5, Φ5, Φ10 e 'ngoe le e 'ngoe 1;

● Boloko bo thata ba Standard Brinell: 2

Tšebeletso ea rona:

Nakong ea ts'ebetso eohle ea khoebo, re fana ka litšebeletso tsa Consultative Selling.

LBH:

Ho feta moo, Haeba mochine oa hau o sa sebetse, o ka re romella e-mail kapa oa re letsetsa re tla leka ka hohle ho fumana bothata ka moqoqo oa rona kapa ka puisano ea video ha ho hlokahala. Ha re se re netefalitse bothata, tharollo e tla fanoa nakong ea lihora tse 24 ho isa ho tse 48.