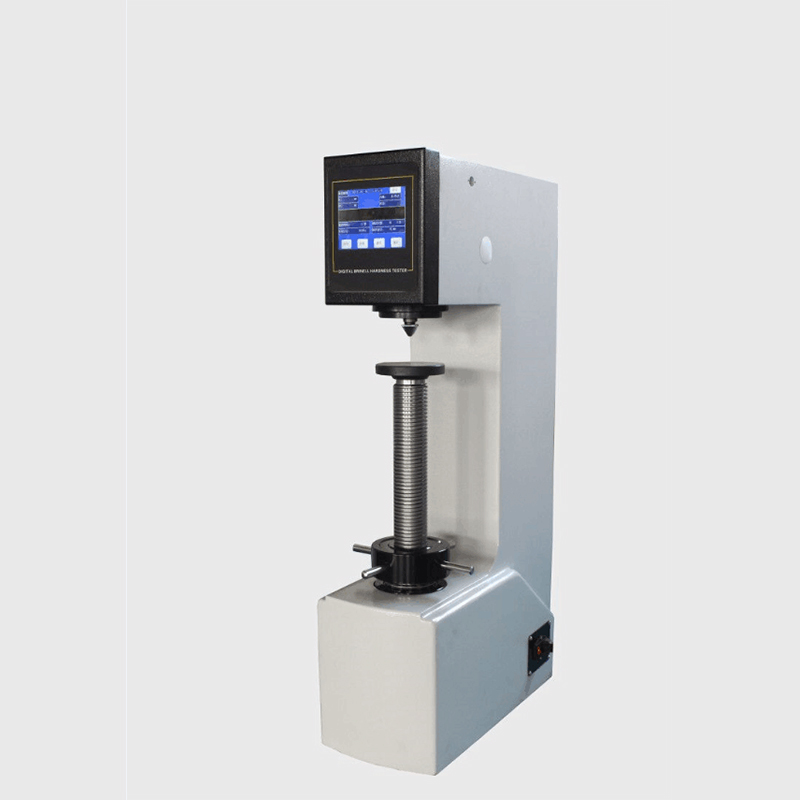

Lihlahisoa

HBS-3000B (ho eketsa boima ba 'mele) tlhahlobo ea boima ba dijithale ea Brinell

Likaroloana

1. E na le mochine o phahameng oa ts'ebetso oa stepper bakeng sa ho kenya le ho laolla ka mokhoa o itekanetseng, lerata le hlahisoang nakong ea teko le lenyenyane;

2. Sebopeho se tiileng, ho tiea ho hotle, ho nepahetse, ho tšepahala, ho tšoarella, le katleho e phahameng ea liteko;

3. Boikarabelo bo feteletseng, boemo bo feteletseng, ts'ireletso ea boiketsetso; ts'ebetso ea tlhahlobo ea othomathike, ha ho phoso ea ts'ebetso ea motho;

4. Kenya bophara ba indentation ka ho toba 'me u bontše ka ho toba boleng ba boima, bo ka lemohang phetoho ea tekanyo leha e le efe ea boima le ho qoba tafole e boima ea ho sheba;

5. E na le mochine o hatisang o hahelletsoeng ka hare, le mokhoa oa boikhethelo oa ts'ebetso ea setšoantšo sa CCD;

6. Ho nepahala ho lumellana le litekanyetso tsa GB/T231.2, ISO6506-2 le American ASTM E10.

Lethathamo la kopo

Bakeng sa ho etsa qeto ea ho thatafala ha Brinell ea ferrous, non-ferrous and bearing alloy materials

Tse kang carbide e entsoeng ka samente, tšepe ea carburized, tšepe e thata, holim'a tšepe e thata, tšepe e thata, aluminiamo alloy, alloy ea koporo, tšepe e bonolo, e tingoeng le e halefileng, tšepe e koetsoeng, tšepe e halikiloeng, joalo-joalo.

Tekheniki parameter

1. Lethathamo la ho lekanya: 5-650HBW

2. Matla a teko: 1838.8, 2415.8, 7355.3, 9807, 2942N

(187.5, 250, 700, 1000, 3000kgf)

3. Bophahamo bo phahameng bo lumelletsoeng ba sampuli: 230mm;

4. Sebaka ho tloha bohareng ba inndenter ho ea leboteng la mochine: 130mm;

5. Qeto ea boima: 0.1HBW;

6. Litekanyo: 700 * 268 * 842mm;

7. Phepelo ea matla: AC220V/50Hz

8. Boima ba 'mele: 210Kg.

Tlhophiso e tloaelehileng

Bench e kholo e bataletseng ea ho sebetsa, benche e nyane e bataletseng, benche e nang le sebopeho sa V: 1 e 'ngoe le e' ngoe;

Indenter ea bolo ea tšepe: Φ2.5, Φ5, Φ10 e 'ngoe le e 'ngoe 1;

Boloko bo thata ba Brinell: 2

Tšebeletso ea rona:

Nakong ea ts'ebetso eohle ea khoebo, re fana ka litšebeletso tsa Consultative Selling.

LBH:

Ho feta moo, Haeba mochine oa hau o sa sebetse, o ka re romella e-mail kapa oa re letsetsa re tla leka ka hohle ho fumana bothata ka moqoqo oa rona kapa ka puisano ea video ha ho hlokahala. Ha re se re netefalitse bothata, tharollo e tla fanoa nakong ea lihora tse 24 ho isa ho tse 48.