Products

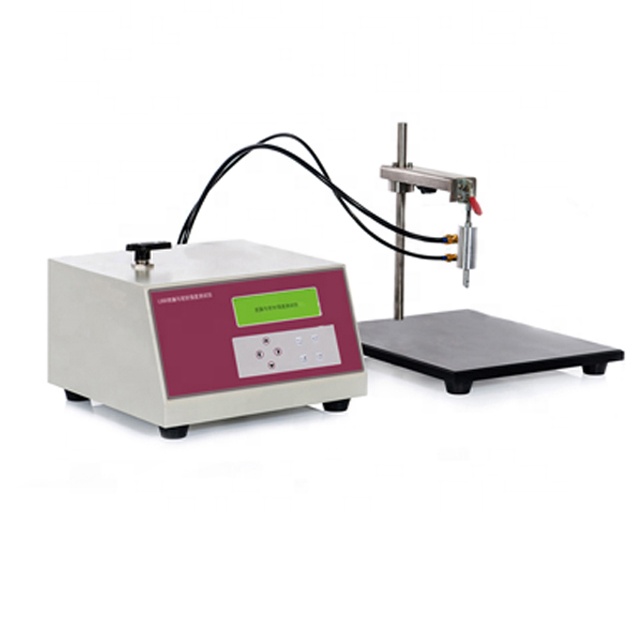

UP-6023 Automatic paint film grading instrument

ISO 2409 Automatic paint film grading instrument

As an important method to evaluate the adhesion degree between coating and substrate, the scratching method has been widely used.Although the traditional manual scratching method is simple and convenient, the cutting speed of the operator and the cutting force of the coating can not be precisely controlled, so that there are some differences in the test results of different testers.The latest ISO 2409-2019 standard clearly states that for uniform cutting, the use of motor driven automatic scribblers is possible.

Advantages:

1 .Adopt 7 inch industrial touch screen, can edit related cutting parameters, parameters display clear and intuitive Cutting speed, cutting stroke, cutting spacing and cutting number (grid number) can be set.

Preset conventional cutting program, one key to complete the grid operation Automatic compensating the load in the cutting process to ensure constant load and consistent cutting depth of the coating

Automatic clamping test sample, simple and convenient.

2. After the completion of a cutting direction, the working platform will automatically rotate 90 degree to avoid the artificial rotation of the cutting line can not be completely vertical crossover

3.Data storage and report output

Main technical parameters

| Test plate size | 150mm×100mm× (0.5 ~ 20) mm |

| Cutting tool load setting range | 1N ~ 50N |

| Cutting stroke setting range | 0mm ~ 60mm |

| Cutting speed setting range | 5mm/s ~ 45mm/s |

| Cutting spacing setting range | 0.5mm ~ 5mm |

| Power supply | 220V 50HZ |

| Instrument dimensions | 535mm×330mm×335mm (length × width × height) |