Products

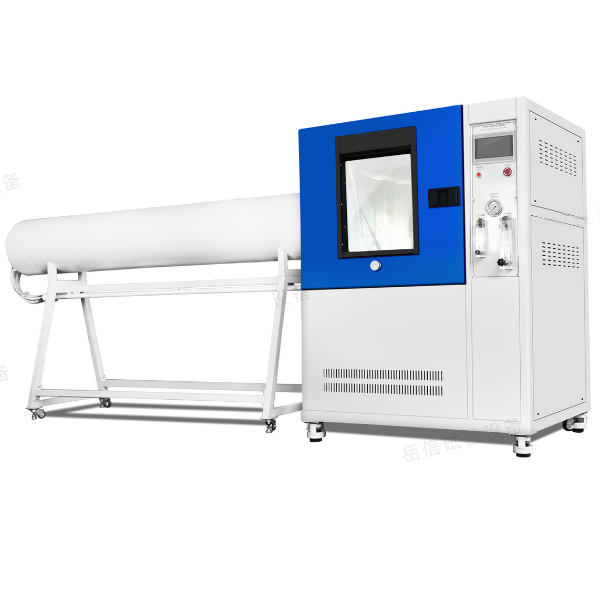

UP-6200 QUV Accelerated Weathering Test Chamber

Characteristic

1. Accelerated Weathering Tester chamber box use numerical control machine processes to shape,the appearance is attractive and beautiful,case cover is bothway flip-cover type, operation is easy.

2.Chamber inside and outside material is imported super #SUS stainless steel,increasing the chamber apperance texture and cleanliness.

3.Heating way is inner tank water channel to heat,heating is quickly and the temperature distribution is uniform.

4.Drainage system uses vortex-flow type and U type sediment device to drainage which is easy to clean.

5.QUV design fit with user-friendly,easy operation, safe and reliable.

6.Adjustable speciman setting up thickness,easy installing.

7. The upward rotating door do not hinder user operation.

8.Unique condesation device only needs tap water to meet demands.

9.Water heater is under of container,longtime life and convenient maintainance.

10.Water level is controlled out of QUV,easy monitoring.

11.Wheel makes moving easy.

12.Computer programming easy and convenient.

13.Irradation calibrator extends longtime life.

14.English and chinese manual.

Technical Parameters

| Model | UP-6200 | |

| Working chamber size(CM) | 45×117×50 | |

| Outside size(CM) | 70×135×145 | |

| Rate of power | 4.0(KW) | |

| Tube number | UV Lamp 8, each side 4

|

|

| Performance

index |

Temperature Range | RT+10℃~70℃ |

| Humidity Range | ≥95%R.H | |

| Tube Distance | 35mm | |

| Distance between sample and tube | 50mm | |

| Supporting sample plate quantity | Length 300mm×Width75mm,About 20 pcs | |

| Ultraviolet wavelength | 290nm~400nm UV-A340、UV-B313、UV-C351 | |

| Tube rate of power | 40W | |

| Control system | Temperature controller | Imported LED,digital P.I.D + S.S.R. Microcomputer integration controller |

| Time controller | Imported programmable time integration controller | |

| Illumination heating system | All autonomous system,nichrome heating. | |

| Condensation Humidity System | Stainless steel surface evaporative humidifier | |

| Blackboard temperature | Thermometal blackboard thermometer | |

| water supply system | Humidification water supply uses automatic controlling | |

| Exposure Way | Moisture condensation exposure and illumination radiation exposure | |

| Safety protection | leakage、short circuit、over-temperature、hydropenia、overcurrent protection | |

Simulating Ultraviolet rays(UV)and sunshine

Although simulating ultraviolet rayis only 5% in the sunshine,it is the illumination factor which effects outdoors products durability declining.This is because sunshine photochemical reaction is increasing along with the wavelength reducing.When simulating the sunshine damaging the physical property of material,don't need to reappear the whole sunshine spectrum.In most situations,just need to simulate the short wave UV.

Fluorescent lamp advantage: quickly to get the result,simplified illuminance controlling, stable spectrum.

UVA-340 It's the best choice to simulate sunshine simulating ultraviolet ray.

UVA-340 Can simulate short wavelength range of the sunshine spectrum.The wavelength range is 295-360nm.

UVA-340 Only can produce the UV wavelength which can be found in the sunshine.

UVB-313, Used in accelerated test to the full extent.UVB-313 can provide the test result quickly.Use the short wavelength which is more strong than the common UV wave.Alough these waves can accelerate the test more fastly to the full extent than the naterual UV wave,it will damage some materials.

Standard definition:Launching luminous energy which wave is 300nm or below is lower 2% of total output luminous energy ,this is one fluorescent lamp,we always call it UV-A light.Launching luminous energy which wave is 300nm or below is larger 10% of total output luminous energy,we always call it UV-B light.UV-A wavelength is 315-400nm,UV-B wavelength is 280-315nm.

Simulating the effect of the rain and dew

The time that outdoor material contacting humidity can be lengthened out to 12hours.The research results show that causing the outdoor humidity is dew not rain.Accelerated Weathering Tester uses a series of unique condensation theory to simulate outdoor humidity effects.In condensing circle of the chamber,there is a water storage tank in the bottom of the chambe and heating it to produce water steam.Hot steam make the chamber humidity is about 100%.This machine designs reasonable which can make sure the test sample can constitute of the chamber side wall,test back will expose in the indoor environment.

Indoor air cooling will result in the surface temperature of the test sample lower several temperature. Difference in temperature will result in test sample surface generated liquid water in the condensation cycle. The condensation product is the stable pure distilled water..It can improve the test efficiency and avoid the water stain problem.

Because the time that outdoor exposure touching humidity can lengthen out to 12 hours,the humidity period of Accelerated Weathering Tester will last several hours.We suggest every condensation period at least 12 hours. Please pay attention that UV exposure and condensation exposure proceeds respectively, it's consistent with the actual condition.

Adopt light source

Use eight rated power rated 40W ultraviolet fluorescent lamp as the light source.The ultraviolet fluorescent lamp tube are distributed in the two-side of the chamber,each side has 4 lights.User can choose UVA-340 or UVB-313.

UV-A wavelength range is 315-400nm, tube luminescent spectrum energy focuses on 340nm.

UV-B wavelength range is 280-315nm, tube luminescent spectrum energy focuses on 313nm;

Because the ultraviolet fluorescent lamp output energy will reduce along with the time lengthening,in order to reduce the bad effect for the test because of energy attenuation,our test chamber every other ultraviolet fluorescent lamp 1/4 lifetime(tube lifetime is:1600H), we will change it a new tube,the replacing place is as below,the ultraviolet fluorescent lamps are constituted by new and old lights,and it will be a constant output light energy.