Products

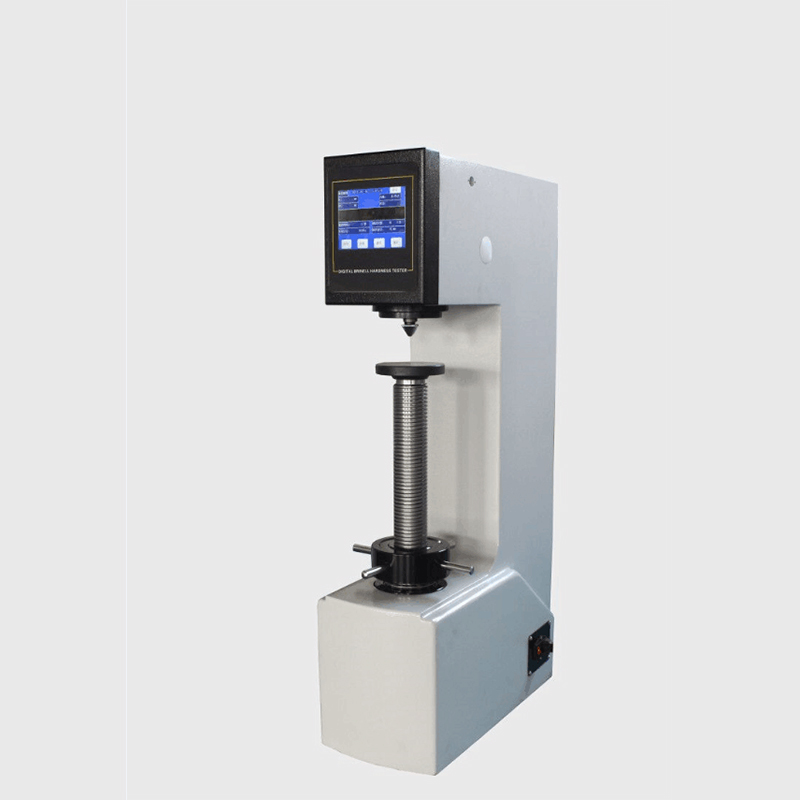

VHBS-3000AET Visual Brinell Hardness Tester

Product introduction

1. VHBS-3000AET visual Brinell hardness tester adopts 8-inch touch screen and high-speed ARM processor, with intuitive display, friendly human-computer interaction, and easy operation; fast calculation speed, massive database storage, automatic data correction, and data line report ;

2. An industrial tablet computer is installed on the side of the fuselage, with a built-in industrial-grade camera, which is processed by CCD image software, directly exporting data and images, and completing manual and automatic measurement of images, which is convenient and fast;

3. The fuselage is made of high-quality cast iron by one-time casting, with the car paint treatment process, the appearance is round and beautiful;

4. Equipped with automatic turret function, automatic switching between indenter and lens, more convenient to use;

5. The maximum and minimum values of hardness can be set. When the test value exceeds the set range, an alarm sound will be issued;

6. With software hardness value correction function, the hardness value can be directly corrected within a certain range;

7. With database function, the test data can be automatically saved in groups, each group can save 10 data, and more than 2000 data can be saved;

8. It has the function of displaying the hardness value curve, which can visually display the change of the hardness value;

9. The unit conversion of the full hardness scale can be automatically performed;

10. The test force is applied by electronic closed-loop control, which fully realizes the automatic operation of loading, holding and unloading;

11. Equipped with high-definition optical dual objective lens, which can measure indentations of different diameters under the standard test force of 31.25-3000kgf;

12. Configure a wireless Bluetooth printer, and output data through RS232 and USB interfaces;

13. Accuracy conforms to GB/T231.2-2018, ISO6506-2 and American ASTM E10 standards.

Specifications

|

Model |

VHBS-3000AET |

|

Measuring range |

5-650HBW |

|

Test force |

306.25、612.9、980.7、1225.9、1838.8、2415.8、4903.5、7355.3、9807、14710.5、29421N (31.25,62.5、100、125、187.5、250、500、750、1000、1500、3000kgf) |

|

Maximum allowable height of the test piece |

280mm |

|

The distance from the center of the indenter to the machine wall |

165mm |

|

Dwell time |

1-99s |

|

Objective magnification |

1X,2X |

|

Hardness Resolution |

0.1HBW |

|

Smallest unit of measure |

5μm |

|

Power supply |

AC 220V,50Hz |

|

Dimensions |

700*268*980mm |

|

Camera resolution |

500W pixels |

|

CCD measurement method |

Automatic and manual |

| Weight | 210kg |

Standard accessories

Large flat workbench: 1

Carbide tungsten carbide ball indenter: φ2.5, φ5, φ10mm, 1 each

Standard Brinell hardness block: 2

V-shaped table: 1

Carbide tungsten carbide balls: 5 pieces each of φ2.5, φ5, and φ10mm

Power cord: 1