Njengenxalenye ebalulekileyo yovavanyo lweepropathi zoomatshini, uvavanyo lwe-tensile ludlala indima ebalulekileyo kwimveliso yoshishino, uphando lwezinto eziphathekayo kunye nophuhliso, njl. Nangona kunjalo, ezinye iimpazamo eziqhelekileyo ziya kuba nempembelelo enkulu ekuchanekeni kweziphumo zovavanyo. Ngaba uziqaphele ezi nkcukacha?

1.Isivamvo samandla asihambelani neemfuno zovavanyo:

I-sensor yamandla yinxalenye ephambili kuvavanyo lwe-tensile, kwaye ukukhetha i-sensor yamandla efanelekileyo kubalulekile. Ezinye iimpazamo eziqhelekileyo zibandakanya: ukungalinganisi i-sensor yamandla, ukusebenzisa i-sensor yamandla kunye noluhlu olungafanelekanga, kunye nokuguga i-sensor yamandla kubangela ukungaphumeleli.

Isisombululo:

Le miba ilandelayo kufuneka ithathelwe ingqalelo xa kukhethwa eyona sensor yamandla ifanelekileyo ngokwesampulu:

1. Nyanzelisa uluhlu lwesivamvo:

Qinisekisa uluhlu olufunekayo lwesivamvo sovavanyo olusekwe kowona mgangatho uphezulu kunye nobuncinci bexabiso leziphumo ezifunekayo kwisampulu yakho yovavanyo. Umzekelo, kwiisampulu zeplastiki, ukuba zombini amandla e-tensile kunye nemodyuli kufuneka ilinganiswe, kuyimfuneko ukuqwalasela ngokubanzi uluhlu lwamandla ezi ziphumo zimbini ukukhetha i-sensor yamandla efanelekileyo.

2. Ukuchaneka nokuchaneka koluhlu:

Amanqanaba okuchaneka okuqhelekileyo kwee-sensor zamandla yi-0.5 kunye ne-1. Ukuthatha i-0.5 njengomzekelo, ngokuqhelekileyo kuthetha ukuba impazamo enkulu evunyelwe yinkqubo yokulinganisa ingaphakathi kwe-± 0.5% yexabiso elibonisiweyo, kungekhona ± 0.5% yesikali esipheleleyo. Kubalulekile ukwahlula oku.

Ngokomzekelo, kwi-sensor ye-100N yamandla, xa ulinganisa ixabiso le-1N amandla, ± 0.5% yexabiso elibonisiweyo yi-± 0.005N iphutha, ngelixa i-± 0.5% yesikali esipheleleyo yi-± 0.5N iphutha.

Ukuchaneka akuthethi ukuba lonke uluhlu luchaneke ngokufanayo. Kufuneka kubekho umda osezantsi. Ngeli xesha, kuxhomekeke kuluhlu oluchanekileyo.

Ukuthatha iinkqubo ezahlukeneyo zokuvavanya njengomzekelo, i-UP2001 & UP-2003 i-sensors ye-series force force inokuhlangabezana ne-0.5 yokuchaneka kwenqanaba ukusuka kwisikali esipheleleyo ukuya kwi-1 / 1000 yesikali esipheleleyo.

Umzobo awufanelekanga okanye umsebenzi awulunganga:

I-fixture yinto ephakathi edibanisa i-sensor yamandla kunye nomzekelo. Indlela yokukhetha i-fixture iya kuchaphazela ngokuthe ngqo ukuchaneka kunye nokuthembeka kovavanyo lwe-tensile. Ukusuka kwimbonakalo yovavanyo, iingxaki eziphambili ezibangelwa ukusebenzisa izixhobo ezingafanelekanga okanye ukusebenza okungalunganga kukutyibilika okanye umhlathi ophukile.

Ukutyibilika:

Okona kutyibilikayo kucace gca komzekelo ngumzekelo ophuma kwindawo okanye ukuguquguquka okungaqhelekanga kwegophe. Ukongeza, inokugwetywa ngokumakisha uphawu kufutshane nendawo yokubambelela phambi kovavanyo ukubona ukuba umgca wokumakisha ukude na kumphezulu obambezelayo, okanye kukho uphawu lotsalo kuphawu lwezinyo lwendawo yomzekelo wokubambisa.

Isisombululo:

Xa i-slippage ifunyenwe, okokuqala qinisekisa ukuba i-clamp manual iqiniswe xa i-clamping isampuli, ingaba uxinzelelo lomoya lwe-pneumatic clamp lukhulu ngokwaneleyo, kunye nokuba ubude be-clamping yesampuli banele.

Ukuba akukho ngxaki ngomsebenzi, qwalasela ukuba i-clamp okanye i-clamp yokukhethwa kobuso ifanelekile. Umzekelo, iipleyiti zentsimbi kufuneka zivavanywe ngobuso obubambeneyo endaweni yobuso obugudileyo, kwaye irabha ene-deformation enkulu kufuneka isebenzise i-self-lock okanye i-pneumatic clamp endaweni ye-flat-push clamps.

Ukwaphuka imihlathi:

Isisombululo:

I-specimen imihlathi iyaphuka, njengoko negama lisitsho, qhawula kwindawo yokubambelela. Ngokufana ne-slipping, kuyimfuneko ukuqinisekisa ukuba uxinzelelo lwe-clamping kwi-specimen lukhulu kakhulu, nokuba i-clamp okanye i-jaw surface ikhethwe ngokufanelekileyo, njl.

Ngokomzekelo, xa uqhuba uvavanyo lwentambo, uxinzelelo lomoya olugqithisileyo luya kubangela ukuba i-specimen iphuke emihlathini, okubangelwa amandla aphantsi kunye nobude; kuvavanyo lwefilimu, imihlathi enerabha egqunywe ngerabha okanye imihlathi eqhagamshelwe ngocingo kufuneka isetyenziswe endaweni yemihlathi exandileyo ukuthintela ukonakalisa umboniso kunye nokubangela ukungaphumeleli kwefilimu kwangaphambi kwexesha.

3. Ulungelelwaniso lwekhonkco lomthwalo:

Ukulungelelaniswa kwekhonkco lomthwalo kunokuqondwa ngokulula ukuba imigca ephakathi ye-sensor yamandla, i-fixture, i-adapter kunye ne-specimen isendleleni echanekileyo. Kuvavanyo lwe-tensile, ukuba ukulungelelaniswa kwekhonkco lomthwalo akulungile, isampuli yovavanyo iya kufakwa kumandla ongezelelweyo okuphazamisayo ngexesha lokulayisha, okubangelwa amandla angalinganiyo kunye nokuchaphazela ukunyaniseka kweziphumo zovavanyo.

Isisombululo:

Ngaphambi kokuba uvavanyo luqale, i-centering ye-chain chain ngaphandle kwe-specimen kufuneka ihlolwe kwaye ilungiswe. Ngalo lonke ixesha i-specimen igxininiswe, qaphela ukuhambelana phakathi kweziko lejometri ye-specimen kunye ne-axis yokulayisha ikhonkco lomthwalo. Ungakhetha ububanzi bokubamba kufutshane nobubanzi bokubamba bomzekelo, okanye ufakele isixhobo esisembindini somzekelo ukuququzelela ukuma kunye nokuphucula ukuphinda-phinda.

4.Ukhetho olungalunganga kunye nokusebenza kwemithombo yoxinzelelo:

Iimathiriyeli ziya konakala ngexesha lovavanyo lwe-tensile. Iimpazamo eziqhelekileyo kwi-strain strain (deformation) yokulinganisa ibandakanya ukukhetha okungalunganga komthombo wokulinganisa ubunzima, ukhetho olungafanelekanga lwe-extensometer, ukufakwa okungafanelekanga kwe-extensometer, ukulinganisa okungalunganga, njl.

Isisombululo:

Ukukhethwa komthombo woxinzelelo kusekelwe kwijometri yomzekelo, ubungakanani bokuguqulwa, kunye neziphumo zovavanyo ezifunekayo.

Umzekelo, ukuba ufuna ukulinganisa imodyuli yeeplastiki kunye neentsimbi, ukusetyenziswa komlinganiselo wokufuduswa komqadi kuya kukhokelela kwisiphumo esisezantsi semodyuli. Ngeli xesha, kufuneka uqwalasele ubude be-specimen gauge kunye ne-stroke efunekayo ukukhetha i-extensometer efanelekileyo.

Kwimicu emide yefoyile, iintambo kunye neminye imizekelo, ukufuduswa komqadi kungasetyenziselwa ukulinganisa ubude bawo. Nokuba usebenzisa umqadi okanye i-extensometer, kubaluleke kakhulu ukuqinisekisa ukuba isakhelo kunye ne-extensometer zibalwa phambi kokwenza uvavanyo lwe-tensile.

Kwangaxeshanye, qinisekisa ukuba i-extensometer ifakwe ngokufanelekileyo. Akufunekanga ikhululeke kakhulu, ibangele ukuba i-extensometer ityibilike ngexesha lovavanyo, okanye iqine kakhulu, ibangele ukuba i-specimen iphuke kwi-blade ye-extensometer.

5.Iisampulu ezingafanelekanga rhoqo:

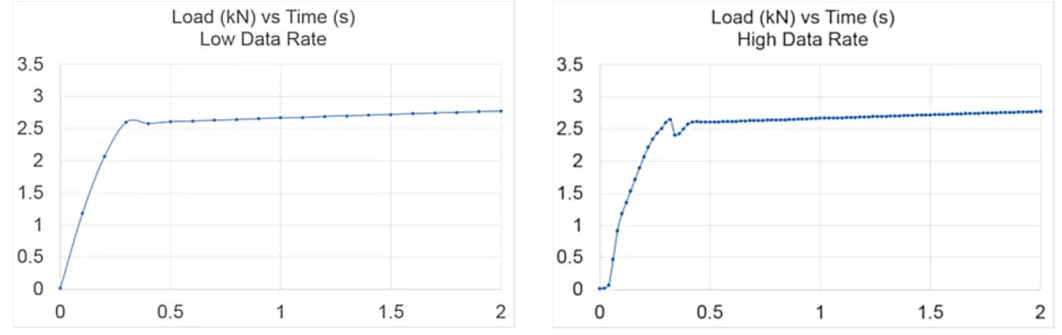

Ubuninzi besampulu yedatha budla ngokungahoywa. Umlinganiselo ophantsi wesampulu unokubangela ukulahleka kwedatha yovavanyo oluphambili kwaye uchaphazele ubunyani beziphumo. Umzekelo, ukuba awona mandla aphezulu ayiqokelelwanga, isiphumo samandla aphezulu siya kuba sisezantsi. Ukuba i-frequency yesampulu iphezulu kakhulu, iya kuba yisampuli engaphezulu, ibangele ukungabikho kwedatha.

Isisombululo:

Khetha ubungakanani besampulu ezifanelekileyo ngokusekwe kwiimfuno zovavanyo kunye neempawu zemathiriyeli. Umgaqo jikelele kukusebenzisa i-50Hz isampuli yefrikhwensi. Nangona kunjalo, kumaxabiso aguquka ngokukhawuleza, isampuli ephezulu yesampulu kufuneka isetyenziswe ukurekhoda idatha.

6. Iimpazamo kwimilinganiselo yobungakanani:

Iimpazamo zomlinganiselo weDimension zibandakanya ukungalilinganisi ubungakanani besampulu eyiyeyona, iimposiso zendawo yokulinganisa, iimpazamo zesixhobo sokulinganisa, kunye neempazamo zegalelo lomlinganiselo.

Isisombululo:

Xa uvavanya, ubungakanani bomzekelo obuqhelekileyo akufanele busetyenziswe ngokuthe ngqo, kodwa ukulinganisa kwangempela kufuneka kwenziwe, ngaphandle koko uxinzelelo lunokuba luphantsi okanye luphezulu kakhulu.

Iindidi zesampulu ezahlukeneyo kunye noluhlu lweesayizi lufuna uxinzelelo olwahlukeneyo lovavanyo kunye nokuchaneka kwesixhobo sokulinganisa ubungakanani.

Isampulu isoloko ifuna ukulinganisa imilinganiselo yeendawo ezininzi ukuya kumndilili okanye uthathe elona xabiso liphantsi. Nika ingqalelo ngakumbi ukurekhoda, ukubala kunye nenkqubo yokufaka ukuthintela iimpazamo. Kucetyiswa ukuba kusetyenziswe isixhobo sokulinganisa ubungakanani obuzenzekelayo, kwaye imilinganiselo elinganisiweyo ifakwa ngokuzenzekelayo kwisoftware kwaye ibalwe ngokwezibalo ukuphepha iimpazamo zokusebenza kunye nokuphucula ukusebenza kakuhle kovavanyo.

7. Impazamo yolungiselelo lweSoftware:

Kungenxa yokuba i-hardware ilungile ayithethi ukuba umphumo wokugqibela ulungile. Imigangatho efanelekileyo yezinto ezahlukeneyo iya kuba neenkcazo ezithile kunye nemiyalelo yokuvavanya kwiziphumo zovavanyo.

Izicwangciso kwisoftware kufuneka zisekelwe kwezi nkcazo kunye nemiyalelo yenkqubo yokuvavanya, njengokulayishwa kwangaphambili, izinga lokuvavanya, ukukhethwa kohlobo lokubala kunye nemimiselo ethile yeparameter.

Ukongeza kwezi mpazamo ziqhelekileyo zingasentla ezinxulumene nenkqubo yovavanyo, ukulungiswa komzekelo, indawo yovavanyo, njl. njl

Ixesha lokuposa: Oct-26-2024