Imikhiqizo

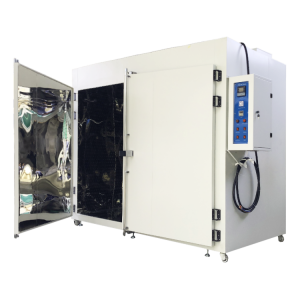

UP-6196 Heat Air Cycling Ihhavini Eyomile

Isingeniso&Izimboni Ezisebenzayo

I-Drying Oven inganikeza indawo yokuhlola ezinzile yokushisisa kwangaphambili, ukomisa, izinguquko mayelana nokuhlolwa kwe-physics kanye nekhemistri. Inikeza isilawuli sokushisa esinembayo esinokuqina okuphezulu kokumelana neplatinamu ekushiseni okwenza izinga lokushisa lisabalale kahle.

Lo mshini unganikeza isikhala sokuhlola esizinzile sokushisisa kwangaphambili, ukomisa, izinguquko mayelana nokuhlolwa kwe-physics kanye nekhemistri. Ihlinzeka ngesilawuli sokushisa esinembayo esinokuqina okuphezulu kokumelana neplatinamu ekushiseni okwenza izinga lokushisa lisabalale kahle.

| Usayizi Wangaphakathi | Usayizi Wangaphandle | Izinga lokushisa | Iyashisa | Ukunemba | Ukufana | Amandla | Amandla omsebenzi |

| W*H*D(cm) | W*H*D(cm) | Ibanga(°C) | Isikhathi | (°C) | (°C) | (kw) | |

| 45×40×40

| 66×82×52

| RT~100°C

| ±0.3

| ±1%

| 220V

| 2.2

| |

| (AD) | |||||||

| 50×50×50 | 69×100×64 | A:200°C | ±0.3 | ±1% | 4.6 | ||

| 60×90×50 | 93×125×70 | B:300°C | ±0.3 | ±1% | 5.5 | ||

| 100×100×60 | 133×165×80 | C:400°C | ±0.3 | ±1% | 6 | ||

| 100×100×100 | 120×160×120 | D:500°C | ±0.3 | ±1% | 8 |

Isici

Insimbi ye-1.Ngaphandle ye-SECC, ukwelashwa kwe-powder coating; I-SUS yangaphakathi #304 insimbi engagqwali.

2. Sebenzisa injini entsha yeshafti ende ekwazi ukumelana nokushisa okuphezulu

3 I-turbine fan.

4.I-Silicone ngenkani

Ukuvikelwa kwe-5.Over lokushisa, i-super load automatic power system.

I-6.Isistimu yokujikeleza: umjikelezo wezinga lamandla omoya.

7. Isistimu yokushisisa:PID+SSR

I-8.I-thermostat: Ukulawula i-microcomputer ye-PID, izinga lokushisa elizenzakalelayo elingaguquki, izinga lokushisa ngokushesha lokunxephezela umsebenzi

9.Isibali sikhathi: izinga lokushisa ukuya esikhathini, lapho inkomba ye-alamu yokuhluleka kwamandla.

10.Ngokwesidingo samakhasimende sokufanisa iwindi lengilazi lingenziwa ngokwezifiso ngokuya ngemininingwane yekhasimende ecacisiwe.

Isevisi yethu:

Phakathi nayo yonke inqubo yebhizinisi, sinikeza isevisi yokubonisana ngokuthengisa.

I-FAQ:

Ngaphezu kwalokho, Uma umshini wakho ungasebenzi, ungasithumelela i-imeyili noma usishayele sizozama konke okusemandleni ethu ukuthola inkinga ngengxoxo yethu noma ngengxoxo yevidiyo uma kunesidingo. Uma sesiyiqinisekisile inkinga, isixazululo sizonikezwa phakathi namahora angu-24 kuya kwangu-48.